China foundry investment casting foundry lost wax casting process part

Leesh Overview

Leesh holdings is the key leading supplier of investment cast parts to both China market and global market.Through many years development, our casting parts now services in railway, automobile and truck, construction machinery, mining machinery, forklift truck, agricultural machinery, ship, petroleum machinery, construction, pump valve, mechanical and electrical, hardware tools, electric power equipment, etc.

Leesh capability

Method: Investment Casting, Lost Wax Casting, Precision Casting

Casting Tolerance: CT5-CT7

Machining Tolerance:+/- 0.005mm,ISO2768-f,ISO-mk

Material: Stainless Steel (General SUS304, SUS316, 1.4301), etc.,Stainless Iron (General 201, 420, 430), etc.,High/Middle/Low Carbon Steel (A3, Q235, 45), etc.,Alloy Steel (General 20cr, 20crmo, 20crnimo, 40cr, 40crmo, 40crnimo, 42cr, 42crmo, 42crnimo) etc.,Brass (H59, H62, H75, H80), etc.,

Red Copper, Bronze, White Copper and other materials.

The above list Is For Reference Only, If You Have Special Needs, Please Contact Customer Service Staff.

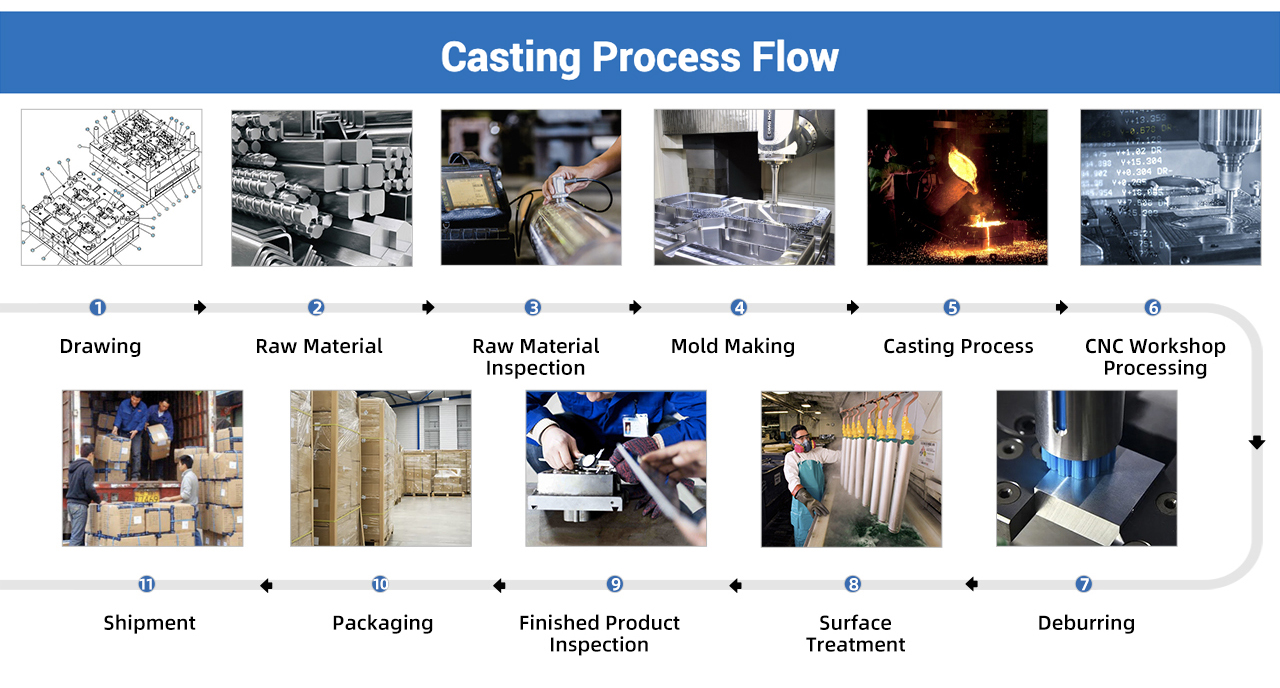

Post Casting Process: Ordinary Polishing, Mirror Polishing, Electrolytic Polishing, Brushed Finishing, Grinding, Heat Treatment, Finishing, Drilling and Tapping,Plating, etc

Surface Treatment: polishing, powder coating, zinc plating, chrome plating,heat treatment,tumbling polishing, electro-polishing.

FAQ:

1: What information does the quotation need?

Pls. offer your drawings and/or samples, quantity and packing’s requirements.

Drawings in PDF, IGS, DWG, STEP, MAX are suitable to us.

2: What’s lead time for samples and products?

Lead time for samples: 15-70 days depend on the structure of the part and other requirements on heat treatment, machining, surface

treatment and so on.

Mass production lead time: 35-70days depend on products’ characteristics and quantity.

3: What is the requirement on payment?

Tooling Cost:100% T/T advanced

Payment for the Order:50% deposit,50% to be paid before shipment.

4: What are surface treatments available?

Powder coating, Shoot Blasting, Painting, Polishing, Acid Pickling, Anodizing, Zinc Plating, Hot-dip Galvanizing, Electrophoresis, Chrome Plating

5: What is the packing?

Normal buck packing suitable for shipment by sea and by air.

We also organize packing according to customers' requirements.