Precision Investment Casting Stainless Steel Pump Casing Body

Introducing our Precision Investment Casting Stainless Steel Pump Casing Body, a robust and meticulously engineered component designed for the demanding requirements of various industrial and commercial fluid handling systems. Crafted from high-grade stainless steel and utilizing the advanced technique of investment casting (also known as lost-wax casting), this pump casing offers an unparalleled combination of durability, structural integrity, and precision.

Superior Material and Durability

The choice of stainless steel as the primary material is fundamental to the component’s performance. Stainless steel provides exceptional resistance to corrosion, rust, and abrasion. This makes our pump casing ideal for use with a wide range of media, including corrosive chemicals, aggressive solvents, high-salinity water, and sanitary fluids. Unlike materials susceptible to rapid degradation, the inherent properties of stainless steel ensure a longer service life, reducing the frequency of maintenance and replacement costs. This durability is crucial for applications in industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and water treatment, where reliable, long-term operation is non-negotiable.

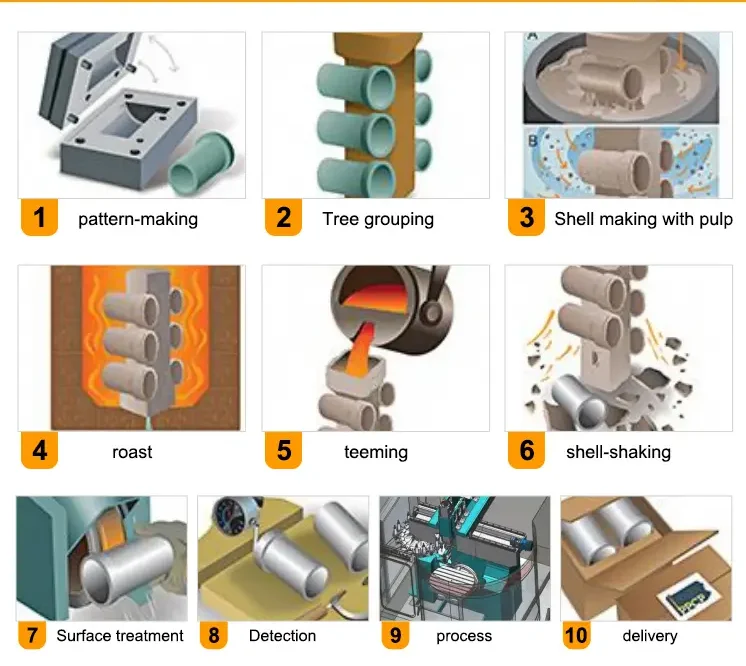

The Advantage of Investment Casting

The superior quality and complexity of the geometry visible in the product images are achieved through the investment casting process. This ‘near-net-shape’ technique involves creating a ceramic mold around a wax pattern, which is then melted out (lost-wax). The resulting mold allows for extremely intricate features, thin walls, and complex internal passages with exceptional dimensional accuracy and a smooth surface finish.

Benefits of Investment Casting for Pump Casings:

- High Precision: The method delivers tight tolerances, minimizing the need for extensive secondary machining. This accuracy is vital for maintaining the efficiency and sealing integrity of the pump, ensuring optimal fluid dynamics and minimizing energy loss.

- Intricate Design: It accommodates complex internal volutes and geometries that are critical for achieving high pump efficiency and managing fluid flow without turbulence.

- Excellent Surface Finish: The smooth finish is inherently beneficial for reducing friction loss and inhibiting the adhesion of process media, which is particularly important in hygienic or sanitary applications.

- Material Integrity: Investment casting ensures a homogenous, dense internal structure, free from the porosity and defects that can compromise performance and leak-proof functionality under high pressure.

Optimized for Performance and Reliability

Our Stainless Steel Pump Casing is engineered to be the heart of any reliable fluid transfer system. The precise wall thickness and flange geometries, as demonstrated in the component, are designed for easy integration and secure, leak-proof connections with other system components, such as piping and motors. Whether the application calls for high pressure or high flow rates, the robust design maintains its structural integrity.

By combining the strength and corrosion resistance of stainless steel with the precision of investment casting, this product is an investment in reliability and efficiency. It serves as a superior alternative to conventionally manufactured or less durable materials, ensuring your pumping operations remain consistent, cost-effective, and safe for years to come. Choose our precision-engineered pump casing for a foundation of excellence in your fluid handling machinery.