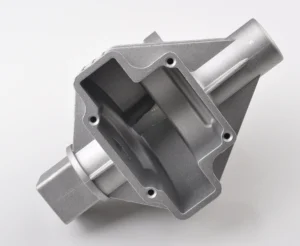

Die Casting Motor Housing: A Superior Product

ADC12/10 and A380 Aluminum Alloys

ADC12/10

ADC12/10 aluminum alloy is renowned for its excellent castability. It can be easily formed into complex shapes through die – casting, which is perfect for the intricate design of motor housings. This alloy also offers good mechanical properties, including decent strength and hardness. It provides reliable protection for the internal components of the motor, withstanding various operating conditions.

A380 Aluminum

A380 aluminum is another prime material for our die – casting motor housing. It has a high strength – to – weight ratio, making the housing both lightweight and robust. This alloy has good thermal conductivity, which is crucial for dissipating heat generated by the motor. It helps in maintaining the optimal operating temperature of the motor, thus enhancing its efficiency and lifespan.

The Die – Casting Advantage

| Manufacturing Method | Die Casting Services |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 Aluminum alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063, AlSi9Cu 2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 Magnesium alloy: AZ91D, AM60B, 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 Zinc alloy: ZA3#,ZA5#,ZA8# |

| Weight Range | 3g – 20 kgs |

| Dimension Range | Mini 80 X 80 mm, Max 800 X 800 mm |

| Tolerance | ±0.02mm |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Ultimate machining tolerance | 0.005mm |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Finish Roughness | Ra0.8-Ra1.6 according to customer requirement |

| Heat Treatment | Normalization , Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |