Austenitic Manganese Steel: A Superior Alloy

Sand Casting Process

Key Properties: Toughness, Ductility, and Wear – Resistance

Toughness and Ductility

Austenitic manganese steel exhibits excellent toughness and ductility. This means it can absorb a significant amount of energy before fracturing, making it suitable for applications where impact resistance is crucial. The austenitic structure of the steel contributes to these properties, as it can undergo a process of strain – induced martensitic transformation under stress. This transformation effectively dissipates energy, preventing sudden failure.

Wear – Resistance

One of the most outstanding features of austenitic manganese steel is its high wear – resistance. When the steel is subjected to abrasion or impact, the surface layer undergoes a transformation that hardens the material. This work – hardening effect significantly increases the steel’s resistance to wear, making it ideal for use in environments where friction and abrasion are common, such as in mining, construction, and industrial machinery.

Standard Grades and Applications

Standard Grades

Common standard grades of austenitic manganese steel include ASTM A128 grades. These grades are defined by specific chemical compositions and mechanical properties. For example, Grade A of ASTM A128 has a minimum manganese content of 11.0% and a minimum carbon content of 1.00%, which contribute to its characteristic properties.

Applications

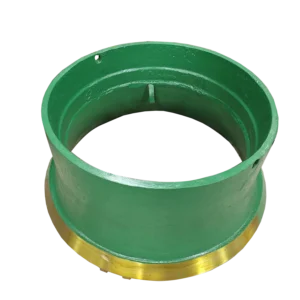

- Mining Industry: In mining equipment like crushers, conveyor systems, and bucket teeth, austenitic manganese steel’s wear – resistance and toughness ensure long – lasting performance. Crushers, for instance, are constantly exposed to high – impact forces and abrasion from rocks, and austenitic manganese steel components can withstand these harsh conditions.

- Construction Industry: Used in construction machinery such as bulldozer blades and excavator buckets. The material’s ability to resist wear and deformation under heavy loads makes it a preferred choice for these applications.

- Industrial Machinery: In parts of mills, mixers, and elevators, where continuous operation exposes components to wear and tear, austenitic manganese steel provides reliable service.

| Manufacturing Method | Sand Casting(Resin Sand, Pre-Coated Sand, Clay Sand, Water glass sand, Green Sand,lost foam ) |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc carbon steel, low carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc. Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, etc. Stainless Steel: SUS 304, 304L, 316, 316L, CF8, CF8M, G-X7CrNiNb1189, etc. AS2074 or according to customer specific requirement. Ductile Iron:A536-Gr.60-40-18,GGG40,GGG50,FCD40,FCD50,Gr370-17,Gr420-12,etc Grey Iron:A48-No.20,25,30,GG10,GG15,GG20,FC10,FC15,FC20,Grade 150,180,220,FGL150,FGL200,FGL250,etc |

| Weight Range | 1 kg to 100 Tons |

| General Casting Tolerance | CT8-CT12 |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Ultimate machining tolerance | 0.005mm |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Finish Roughness | Ra12.5-Ra25 according to customer requirement |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Heat Treatment | Normalization, Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |