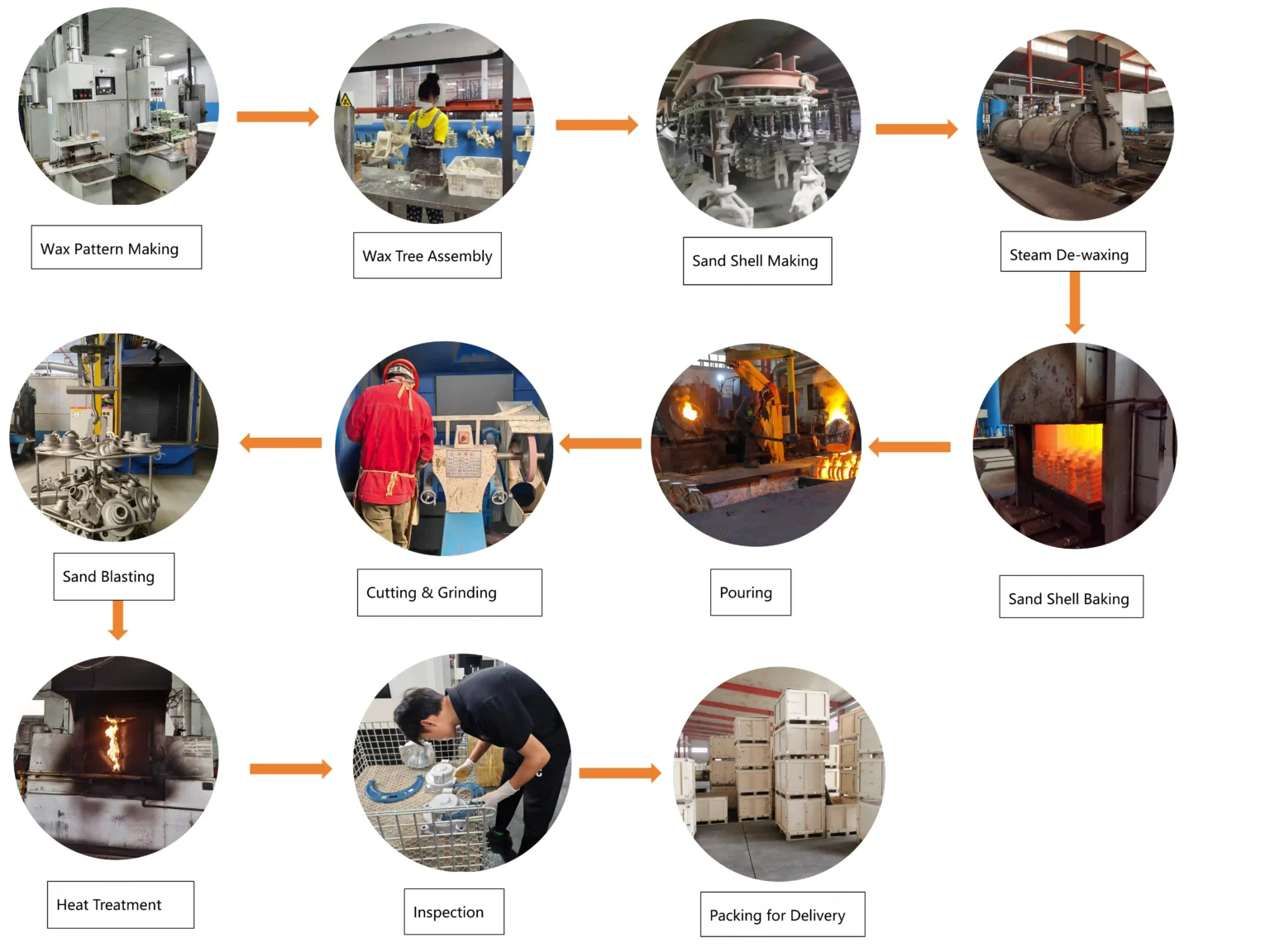

Lost Wax Casting, also known as Investment Casting, features high precision, excellent surface finish, and net-shape forming.

Leesh capability

Method: Investment Casting, Lost Wax Casting, Precision Casting

| Process Description | Process Control | |||

| Mass(kgs) | General Tolerance Standard | Casting Tolerance(CT) | Surface Rougness(μm) | |

| Silicon Sol | 0.05-50 | ISO 8062 | CT4-CT6 | Ra 3.2~6.3 μm |

| Water Glass | 0.10-100 | ISO 8062 | CT6-CT8 | Ra 6.3~12.5 μm |

Stainless Steel (General SUS304, SUS316, 1.4301, ASTM A351M/A743M CF8M (EN10213/EN10283 1.4408)), etc.,

Stainless Iron (General 201, 420, 430), etc.,

Duplex Steel ASTM A890/A890M 6A

Super Austenitic Steel 654SMo/(S32654, 1.4652)

High/Middle/Low Carbon Steel (A3, Q235, 45,1045), etc.,

Alloy Steel (General 20cr, 20crmo, 20crnimo, 40cr, 40crmo, 40crnimo, 42cr, 42crmo, 42crnimo) etc.,

Brass (H59, H62, H75, H80), etc.,

Red Copper, Bronze, White Copper and other materials.

The above list Is For Reference Only, If You Have Special Needs, Please Contact Customer Service Staff.

Post Casting Process:

Ordinary Polishing, Mirror Polishing, Electrolytic Polishing, Brushed Finishing, Grinding, Heat Treatment, Finishing, Drilling and Tapping,Plating, etc

Surface Treatment:

polishing, powder coating, zinc plating, chrome plating,heat treatment,tumbling polishing, electro-polishing.

Except the Lost wax casting process, Leesh more activies as below:

Activities

–Casting Services–Sand Casting,Die Casting

–Forging– Die Forging, Hot Forging,Net Shape Forging

–Machining – CNC, NC, Cutting, Milling, Boring and Drilling Process

–Fabrication-Welding,Cutting,Bending,Stamping,Punching

–Industries Rubber & Polyurethane parts

–Standard & non-standard spare parts supply

–Pipe Fittings– Seamless and Welded Pipe, fittings,flanges, etc