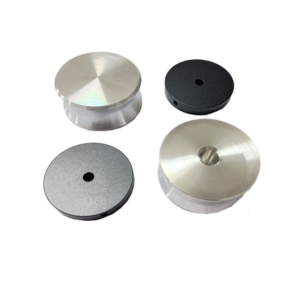

Delrin Machine Parts: A Blend of Materials

Anodised Coating: Adding Value to Delrin Parts

Benefits of Anodised Aluminum on Delrin

Corrosion Resistance: The anodised aluminum coating acts as a barrier, safeguarding the Delrin part from moisture, chemicals, and other corrosive agents. This is particularly important in industrial environments where parts are exposed to harsh conditions.

Enhanced Aesthetic Appeal: Anodising can be customized to produce a range of colors and finishes, adding an aesthetic touch to the Delrin machine parts. This not only makes the parts more visually appealing but also allows for easy identification and branding.

Improved Hardness: The anodised layer increases the hardness of the part’s surface, reducing the risk of scratches and abrasion. This helps to maintain the integrity of the Delrin part over its lifespan, ensuring consistent performance.

Applications of Delrin Machine Parts with Anodised Coating

| Manufacturing Method | High Precison Machining,CNC Machining |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Metal: Aluminum , Copper , Brass , Steel, Stainless Steel, Titanium and etc. Plastic: ABS, POM, PP, PU, PC,PA66, PMMA, PVC, PVE, Nylon and etc. |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| General Tolerance | ±0.05mm |

| Ultimate machining tolerance | ±0.01mm |

| Machining Roughness | Ra0.8-Ra3.2 according to customer requirement |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching. |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |