Precision in Carbon Steel Investment Casting

Augers: A Key Product

Drill Augers

Drill augers are designed to bore through various materials, from soil in construction projects to wood in forestry applications. The carbon steel used in the water glass lost – wax casting process endows the drill augers with high strength and wear resistance. The precision of the casting ensures that the auger’s helical shape is accurately formed, enabling efficient material removal and smooth drilling operations.

Feed Augers

Feed augers play a crucial role in industries such as agriculture and food processing. They are responsible for transporting materials, like grains or animal feed, from one point to another. The carbon steel construction of these feed augers, achieved through water glass lost – wax precision investment casting, provides durability to withstand the abrasive nature of the materials being conveyed. The smooth surface finish obtained from the casting process also helps in preventing material buildup, ensuring a continuous and efficient feeding process.

Cast augers are often used in industrial applications where a robust and precisely – shaped auger is required. Whether it’s for mixing substances in chemical plants or moving materials in mining operations, the carbon steel cast augers produced through this process offer excellent mechanical properties. The investment casting method allows for the creation of complex geometries, ensuring that the cast augers can meet the specific requirements of different industrial processes.

Quality Assurance

|

Item

|

Value

|

|||

|

Product Name

|

High precision investment casting part/ Lost wax casting part

|

|||

|

Material

|

Stainless steel, carbon steel, alloy steel, titanium alloy or customized

|

|||

|

Brand Name

|

Customized

|

|||

|

Design Support

|

PDF, 3D, step files or samples are all accepted.

|

|||

|

Quality Control

|

100% one by one full insepction before packing

|

|||

|

Surface Treatment

|

E-coating,Zinc ,Polishing, Sandy blasting, galvanize, Powder coating

|

|||

|

Application

|

Automotive manufacturing, lighting photography, aerospace, cosmetics, food and chemical industry, medical equipment, new energy,heavy machinery and construction industry, etc.

|

|||

|

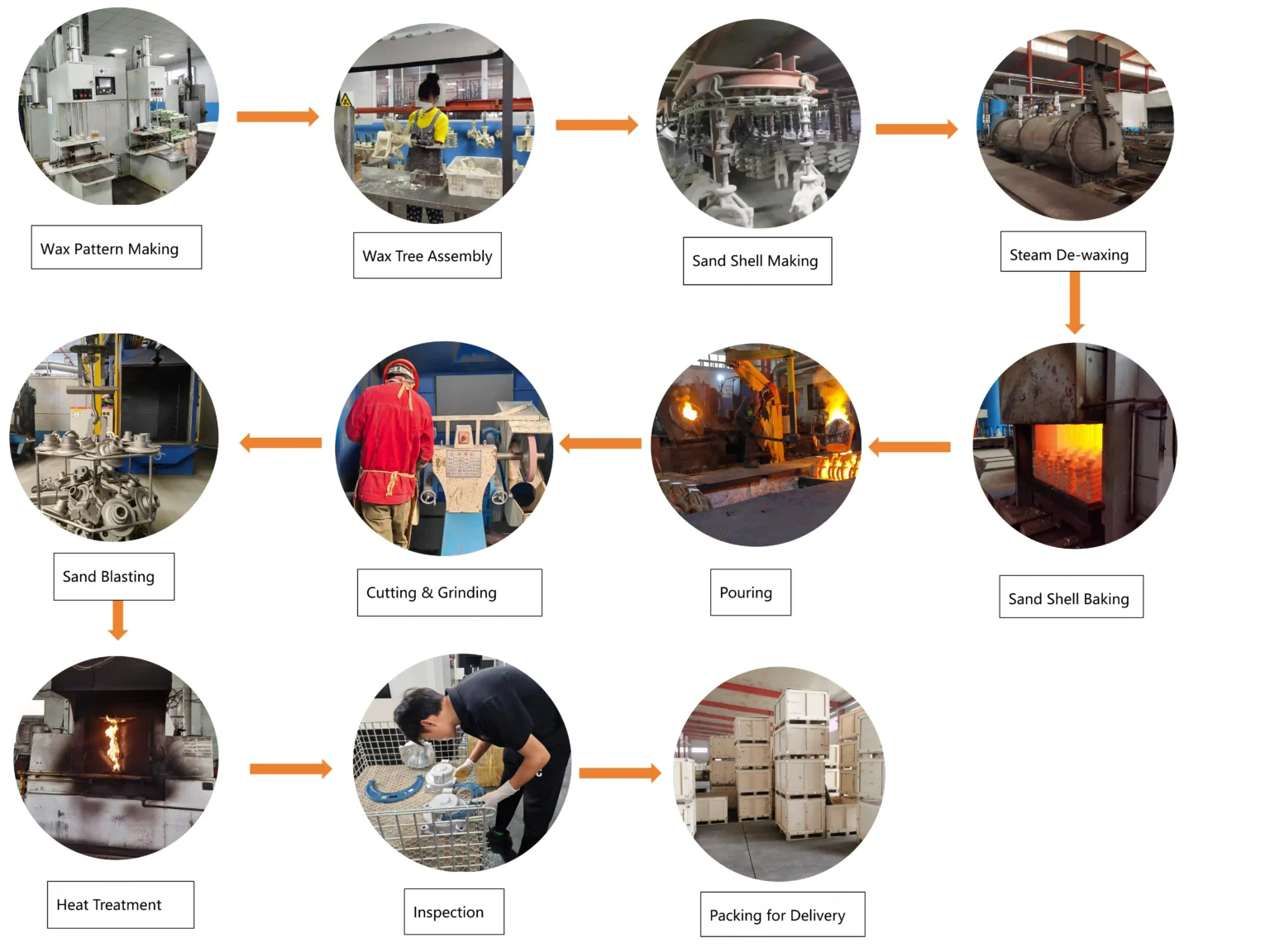

Process

|

Mold+Injection Wax+Dewax+Casting +Machining(if Need)+surface Treatment

|

|||

|

Machining

|

Drilling, Reaming, Tapping, CNC Lathe, CNC machining Center &Milling, Wire EDM, etc.

|

|||

|

Service

|

OEM/ODM and solutions, small orders are welcomed.

|

|||

|

Tolerance

|

ISO 8062 CT5-CT7 | |||

| Inspection | CMM | |||

|

Size

|

2mm–620mm

|

|||

|

Lead Time

|

3-5 days for samples, 20-35 days for bulk orders.

|

|||