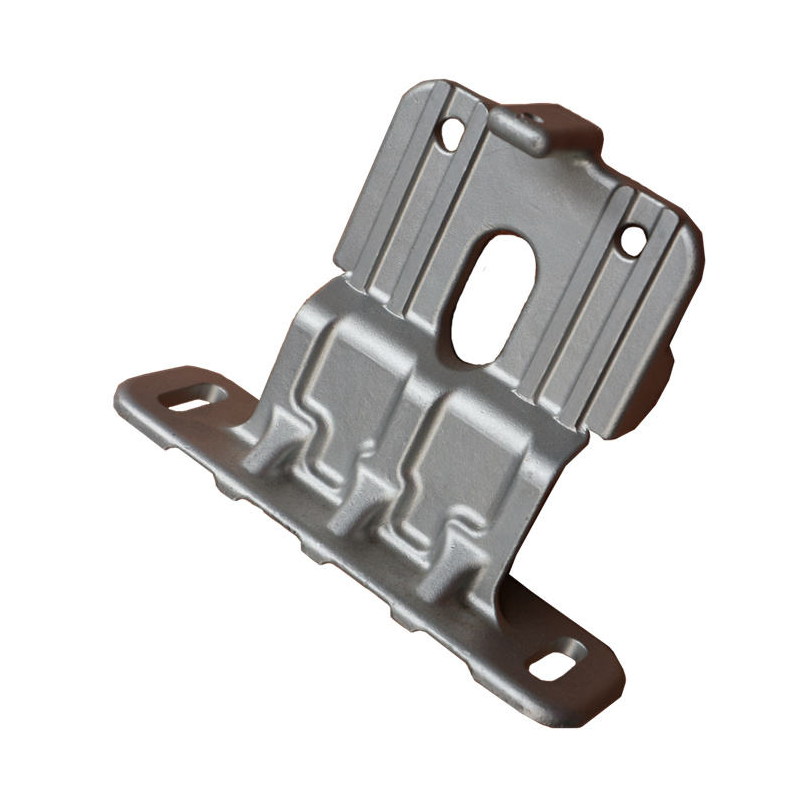

Net Shape Casting

Advantages of Net Shape Casting

- Minimal Machining

One of the most significant benefits of net shape casting is that it often requires little to no machining. The process allows for the creation of components that are very close to their final shape right from the casting stage. This not only saves time but also reduces production costs associated with machining operations. In contrast to sand casting, where significant machining is usually necessary to achieve the desired final dimensions and surface finish, net shape casting can produce parts that are ready to use with only minor finishing touches, if any.

- Excellent Surface Finish

Net shape casting provides an excellent surface finish. The use of a wax pattern in the lost – wax process (a common form of net shape casting) results in a smooth surface on the final cast component. This smooth finish is far superior to that of sand – cast parts, which typically have a rougher surface due to the nature of the sand mold. A better surface finish means that the parts can be used in applications where aesthetics are important or where a smooth surface is required for functional reasons, such as in components with moving parts.

- Suitability for All Kinds of Alloy Steels

Net shape casting is highly adaptable to all kinds of alloy steels. Whether it’s high – strength alloy steels used in aerospace applications or corrosion – resistant alloy steels for marine environments, this casting method can handle the unique properties of different alloys. The precision of the process ensures that the alloy steel components maintain their mechanical properties and integrity during the casting process, resulting in high – quality parts that meet the stringent requirements of various industries.

Applications

As a leading Cast Parts Manufacturer in China, we provides high-quality investment casting services, specializing in the production of precision valve body components. As shown in our facility, we handle high-volume orders for complex parts, from raw casting to finished product. Using advanced investment casting techniques, we manufacture durable valve body parts in various alloys, including stainless steel and bronze. We are an OEM partner for your industrial needs.

| Manufacturing Method | Investment Casting(Lost Wax Casting) |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Carbon steel, Low carbon steel, Middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc. Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, etc. Stainless Steel: SUS 304, 304L, 316, 316L, CF8, CF8M, G-X7CrNiNb1189, AS2074 or according to customer specific requirement. Copper, Brass, Bronze |

| Weight Range | 0.01 kgs to 100 kgs |

| Cast Hole Min. Dia. | Ø2mm |

| General Casting Tolerance | CT4-CT7 |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Ultimate machining tolerance | 0.005mm |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Finish Roughness | Ra1.6-Ra3.2 according to customer requirement |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Heat Treatment | Normalization, Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |

Investment casting, also known as lost wax casting, is a casting method in which a pattern is made of a melt-able material, then coated with several layers of refractory material to form a shell, and the pattern is melted away after high-temperature firing, and then the molten metal is poured into the shell.

Investment casting have high precision and high surface quality, with small machining allowances, which can achieve less or no machining requires. Investment casting can cast complex thin-walled parts with complex shapes (the minimum wall thickness can reach 0.25-0.4mm), and the smallest hole diameter can reach 2.5mm.

The process normal as below:

Drawing Review ->Tooling Designing ->Tooling Manufacturing ->Wax Pattern Making ->Pattern Tree Assembly ->Dipping and Coating ->De-waxing and Firing- Pouring-Knockout ->Grinding ->Heat Treatment -> Machining(if requires) ->Inspection->Delivery

Leesh holdings is the key leading supplier of investment cast parts to both China market and global market.Through many years development, our casting parts now services in railway, automobile and truck, construction machinery, mining machinery, forklift truck, agricultural machinery, ship, petroleum machinery, construction, pump valve, mechanical and electrical, hardware tools, electric power equipment, etc.

Leesh capability

Method: Investment Casting, Lost Wax Casting, Precision Casting

| Process Description | Process Control | |||

| Mass(kgs) | General Tolerance Standard | Casting Tolerance(CT) | Surface Rougness(μm) | |

| Silicon Sol | 0.05-50 | ISO 8062 | CT4-CT6 | Ra 3.2~6.3 μm |

| Water Glass | 0.10-100 | ISO 8062 | CT6-CT8 | Ra 6.3~12.5 μm |

Material:

Stainless Steel (General SUS304, SUS316, 1.4301), etc.,

Stainless Iron (General 201, 420, 430), etc.,

High/Middle/Low Carbon Steel (A3, Q235, 45), etc.,

Alloy Steel (General 20cr, 20crmo, 20crnimo, 40cr, 40crmo, 40crnimo, 42cr, 42crmo, 42crnimo) etc.,

Brass (H59, H62, H75, H80), etc.,

Red Copper, Bronze, White Copper and other materials.

The above list Is For Reference Only, If You Have Special Needs, Please Contact Customer Service Staff.

Post Casting Process:

Ordinary Polishing, Mirror Polishing, Electrolytic Polishing, Brushed Finishing, Grinding, Heat Treatment, Finishing, Drilling and Tapping,Plating, etc

Surface Treatment:

polishing, powder coating, zinc plating, chrome plating,heat treatment,tumbling polishing, electro-polishing.

We understand your concerns about the quality, we have bought full sets of advanced inspection facilities,Spectrum analyzer, metallographic microscope, tensile testing machine, low temperature impact testing machine, X-ray flaw detection machine, magnetic particle flaw detection machine, ultrasonic flaw detection machine, coordinate measuring instrument, image measuring instrument. The above equipment can ensure the supply of high-standard precision castings to customers, and meet customers’ comprehensive testing requirements for physical and chemical properties of materials, non-destructive defect testing, and high-precision geometric size testing.

https://chinafoundrygroup.com/investment-casting-service/