What is Shell Mold Casting?

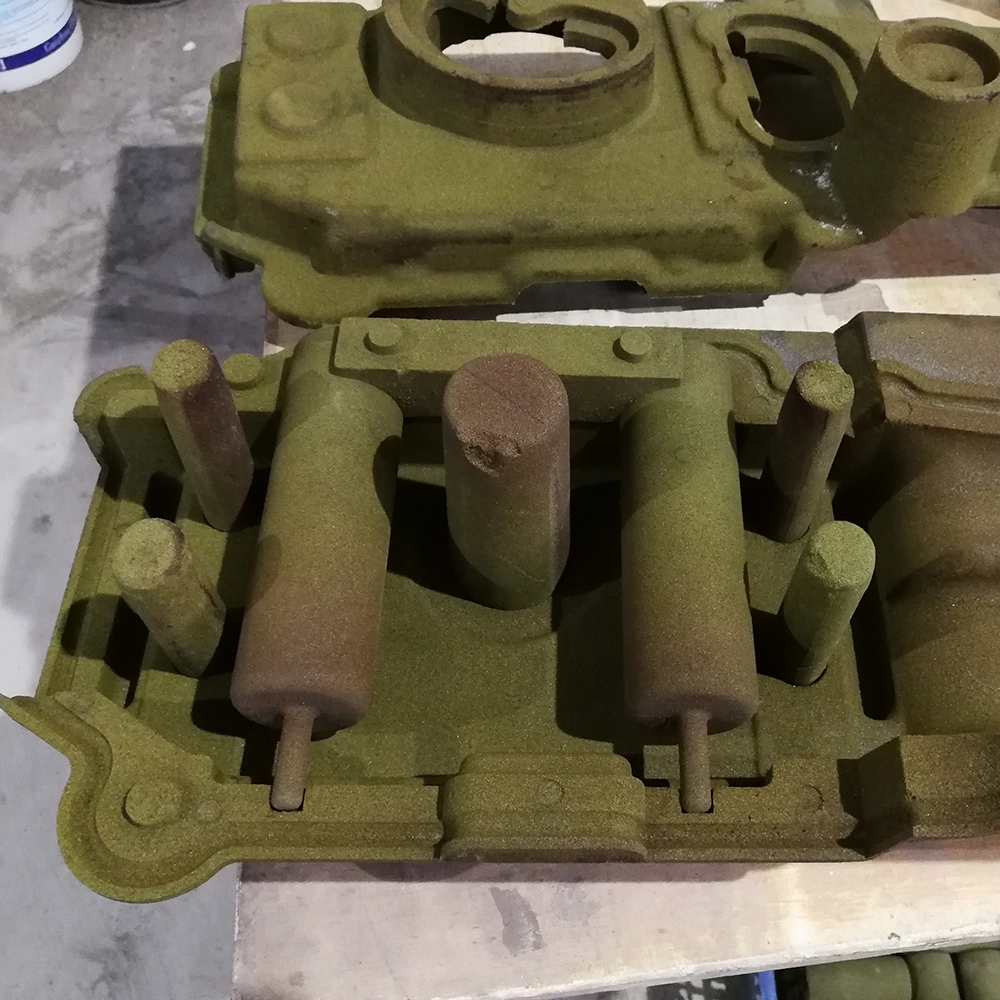

Shell Mold Casting is a specialized casting process known for its ability to produce high – precision parts. It involves creating a thin, hardened shell around a pattern and also put the Shell Core inside the Shell Mold. This shell acts as the mold for pouring molten metal. The process offers excellent dimensional accuracy and surface finish, making it suitable for a wide range of industries.

Leesh Resin Sand Casting Service

Shell Mold Casting is once casting method of Leesh’s Resin Sand Casting Service which is suitable for high precison sand casting requirments.

But the Shell Mold Casting always has weight limit from few dozens grams to dozens kgs.

Hot Shell Molding Castings

Hot shell molding is a key aspect of shell mold casting. In this process, the pre – coated resin sand is heated to a specific temperature, usually around 250 – 300°C. The heated sand is then applied to a heated pattern. As the sand contacts the pattern, the resin binder melts and bonds the sand particles together, forming a hard shell. This shell is strong enough to hold the molten metal during pouring, resulting in Hot Shell Molding Castings with precise dimensions.

Core Casting Process

The core casting process in shell mold casting is used to create internal cavities in the castings. Cores are made from pre – coated resin sand and placed inside the shell mold before pouring the molten metal. These cores are designed to withstand the heat of the molten metal and maintain their shape, ensuring the accurate formation of internal features in the final casting.

In conclusion, shell mold casting, along with Leesh’s Resin Sand Casting Service, offers a reliable and efficient solution for producing high – quality castings. Whether it’s hot shell molding or core casting, the process can meet the diverse needs of various industries.

| Manufacturing Method | Sand Casting(Resin Sand, Pre-Coated Sand, Clay Sand, Water glass sand, Green Sand,lost foam ) |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc carbon steel, low carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc. Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, etc. Stainless Steel: SUS 304, 304L, 316, 316L, CF8, CF8M, G-X7CrNiNb1189, etc. AS2074 or according to customer specific requirement. Ductile Iron:A536-Gr.60-40-18,GGG40,GGG50,FCD40,FCD50,Gr370-17,Gr420-12,etc Grey Iron:A48-No.20,25,30,GG10,GG15,GG20,FC10,FC15,FC20,Grade 150,180,220,FGL150,FGL200,FGL250,etc |

| Weight Range | 1 kg to 100 Tons |

| General Casting Tolerance | CT8-CT12 |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Ultimate machining tolerance | 0.005mm |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Finish Roughness | Ra12.5-Ra25 according to customer requirement |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Heat Treatment | Normalization, Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |

Common FAQs About Leesh Sand Casting

1. What is sand casting?

Sand casting is a casting method that uses sand as the molding material to produce castings. It is widely used due to its advantages such as readily available and low-cost materials, simple equipment, easy operation, and no restrictions on casting alloy types, shapes, sizes, or production scales.

2. What materials can Leesh supply for sand casting?

Leesh provides various materials including Carbon Steel, Alloy Steel, Stainless Steel, Grey Iron, and Ductile Iron. These materials comply with international and national standards such as ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB.

3. What is the weight range of castings Leesh can produce?

- Cast Steel: 50Kg – 25,000Kg

- Cast Iron: 0.1Kg – 3,000Kg

4. What sand casting processes does Leesh adopt?

- For Cast Steel: Water glass sand, resin sand, coated resin sand (Hot-Box & Shell Molding)

- For Cast Iron: Resin sand, green sand

5. What are the key technical specifications of Leesh’s Green sand casting?

- Dimensional tolerance: CT8–CT12 (per ISO 8062)

- Surface roughness: Ra 6.3–25 μm

- Max part weight: 0.1 kg – 25,000 kg

6. Which industries does Leesh’s sand casting serve?

Leesh’s sand casting solutions are suitable for diverse industries including construction, machinery, automotive, and energy.

7. Why choose Leesh’s sand casting services?

- Cost-effective for both small and large production runs

- Compatible with a wide range of metals and alloys

- Flexible in design and size customization

- Shorter lead times for prototype development and bulk production