04 November, 2025

ASTM A890/A890M

Standard Specification for Corrosion-Resistant Iron-Chromium-Nickel-Molybdenum

Duplex Stainless Steel (Austenitic/Ferritic) Steel Castings...

17 October, 2025

Common Defects in Castings

During many years’ practical experience, the Leesh engineer team has made notes on common casting defects, helping people...

21 August, 2025

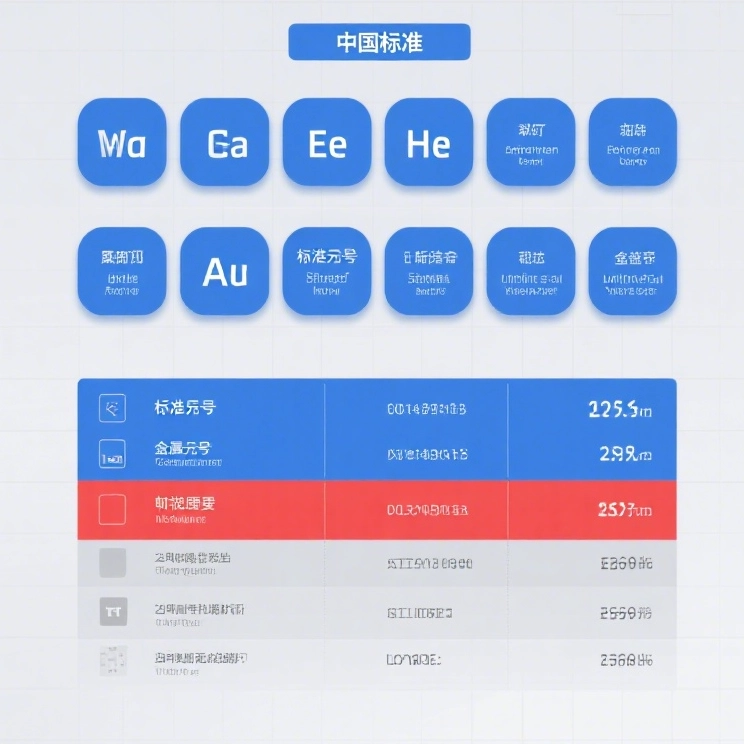

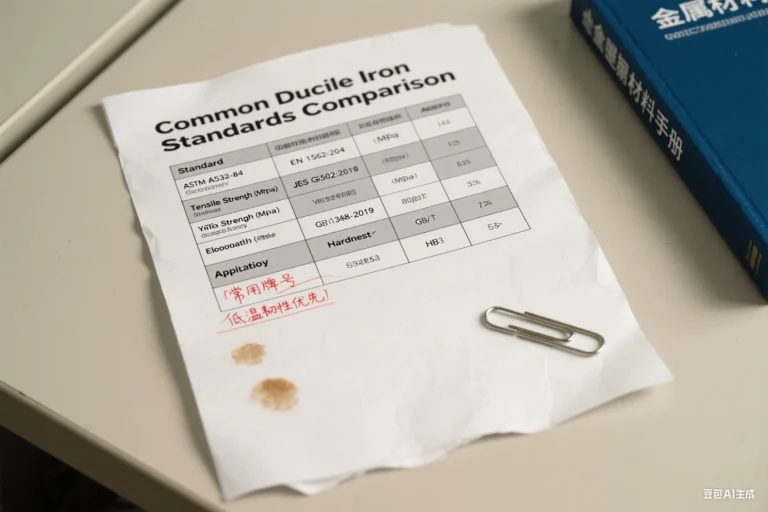

China and Japan Ferrous Metal Standard comparison

21 August, 2025

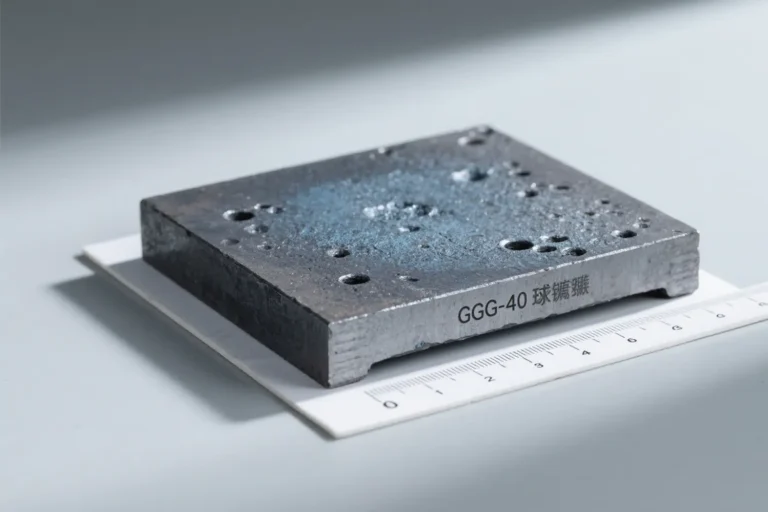

Cast iron GGG40 is a low grade of ductile iron. Leesh Holdings' foundry has pouring this material for many years.

If you have any RFQ, please don't...

21 August, 2025

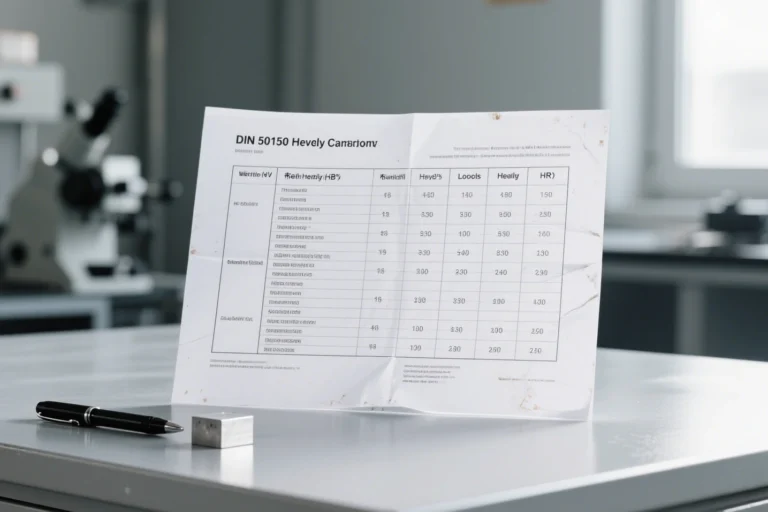

DIN 50150 :Vickers hardness, Brinell hardness and Rockwell hardness Conversion Sheet

Noted: This sheet only for your reference, please don’t take...

21 August, 2025

Metallography Inspection

Hardness Inspection

Pressure Testing

Ultrasonic inspection

21 August, 2025

Manual moulding

Manual moulding refers to the moulding process of using hand or hand tools to complete the main operations such as place tooling, compact...

21 August, 2025

Beased on many years casting expericne ,Leesh casting engineer team sharing some knowledge of the Casting Alloy fluidity

1-Concept of alloy fluidity

2-Method...

21 August, 2025

Precision casting, also known as investment casting or lost wax casting, is a manufacturing process that has been used for centuries to create highly detailed...

No posts found