What is Close Die Forging?

Close die forging, a complex shape metal – forming process. In this process, a heated metal billet is placed between two dies. As the dies come together under immense pressure, the metal is forced to conform to the intricate shape of the die cavity. This results in parts with exceptional dimensional accuracy and a refined surface finish with less or no machining request.

The Process of Close Die Forging

The close die forging begins with die design. At Leesh our engineer team will desin the die as per customers’ drawing or model, after desgining, we will send to our machining shop for forging die maufacturing. Once the dies are ready, the metal billet is heated to its required forging temperature. This temperature varies depending on the type of metal, ensuring maximum malleability. The heated billet/raw material is then precisely positioned between the dies. A strong press then closes the dies, shaping the metal into the desired form. Post forging, the part will send to heat treatment to enhance its mechanical properties.

In most of the time, not only one die, it may 2 or 3 or more further dies to complete the finial shape.

Advantages of Close Die Forging

One of the primary benefits of close die forging is the high level of precision it offers. The process allows for the production of complex shapes with tight tolerances, reducing the need for extensive machining. Additionally, the forging process aligns the metal’s grain structure, resulting in parts that are stronger and more durable. This makes close die – forged components ideal for applications where reliability and performance are paramount, such as in the automotive, aerospace, and defense industries.

Leesh Close Die Forging Service

Leesh Die Forging Service already has decades of development, currently serves the auto, agriculture, earth moving, mining, and oil industries.

Based on the Leesh philosophy:

Integrity · Customer Focus · Commitment to Performance · Social Responsibility

Leesh has gained global reputation.

Based on the Leesh philosophy:

Integrity · Customer Focus · Commitment to Performance · Social Responsibility

Leesh has gained global reputation.

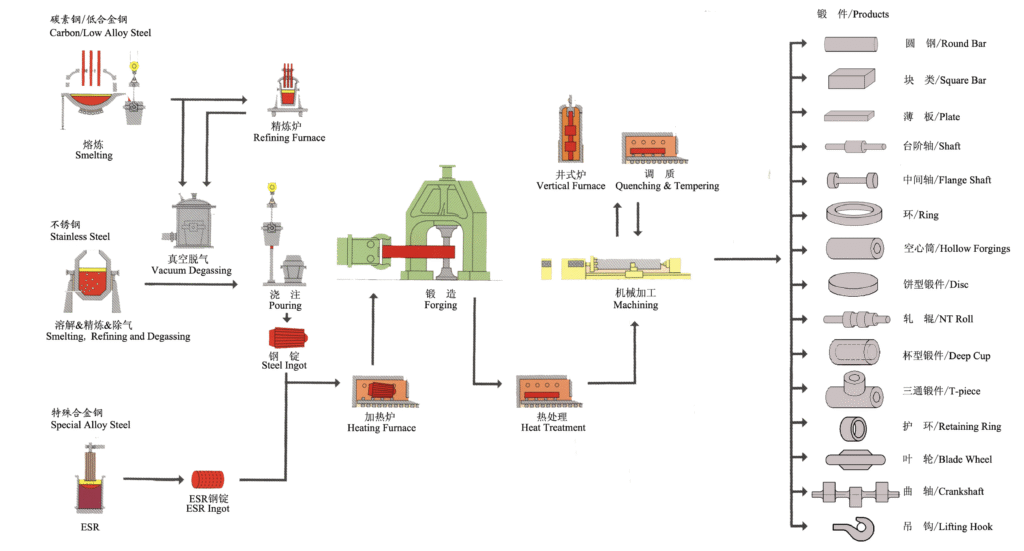

Leesh Foring Process

State-of-the-art manufacturing process ensuring highest quality standards

Hot Forging Materials We Use

High-quality steel materials for superior performance and durability

Carbon & Low Alloy Steel

Carbon Steel:

35, 45, CK22N, Q235

35, 45, CK22N, Q235

Mn Series:

16Mn, 20Mn2, 50Mn

16Mn, 20Mn2, 50Mn

Cr Series:

20Cr, 40Cr

20Cr, 40Cr

Structural Alloy Steel

Si-Mn:

20SiMn, 37SiMn2MoV

20SiMn, 37SiMn2MoV

Cr-Mo:

35CrMo, 42CrMo

35CrMo, 42CrMo

Cr-Ni-Mo:

34CrNiMo, 40CrNiMo

34CrNiMo, 40CrNiMo

Specialty Steels

Stainless Steel:

1Cr18Ni9Ti, 1Cr13

1Cr18Ni9Ti, 1Cr13

Super Alloy:

GH1, GH2, GH3, GH4 Series

GH1, GH2, GH3, GH4 Series

Refractory:

F91, F92, 15Cr2MoV

F91, F92, 15Cr2MoV

Pressure Vessel Steel

Standard:

09MnNiD, 16MnD

09MnNiD, 16MnD

Mo Alloy:

20MnMo, 15CrMo

20MnMo, 15CrMo

Certification:

ASME, GB Standards

ASME, GB Standards

Nuclear Power Steel

ASTM:

SA-182 Series

SA-182 Series

Pressure:

SA-266 Series

SA-266 Series

Grade:

Nuclear Quality

Nuclear Quality

Custom Materials

Composition:

Tailored to Requirements

Tailored to Requirements

Testing:

Full Material Analysis

Full Material Analysis

Documentation:

Complete Traceability

Complete Traceability

Applications of Hot Forging

Net shape forging is widely used in industries requiring high-strength, precision components with minimal production costs. Below are the key application areas and typical components:

Automotive

- Connecting rods

- Crankshafts

- Gear blanks

- Steering components

- Suspension parts

Aerospace

- Turbine blades

- Engine brackets

- Landing gear components

- Hydraulic fittings

- Structural forgings

Energy

- Wind turbine shafts

- Power generator components

- Oil & gas valves

- Pipeline fittings

- Nuclear reactor parts

Heavy Machinery

- Excavator bucket teeth

- Bulldozer linkages

- Crane hooks

- Transmission gears

- Hydraulic cylinder rods