What is the Drop Forging Process?

Types of Drop Forging Processes

Hot Drop Forging Process

In the hot drop forging process, the metal workpiece is heated to a high temperature, typically above its recrystallization temperature. This makes the metal more malleable, allowing it to be easily shaped under the impact of the hammer or press. Hot drop forging is suitable for large – scale production and for working with metals like carbon steel and alloy steel. It can produce complex shapes with good grain flow, enhancing the mechanical properties of the final product.

Cold Drop Forging Process

The cold drop forging process, on the other hand, is carried out at room temperature. This process offers higher dimensional accuracy and a better surface finish compared to hot forging. However, it requires more force to deform the metal, as it is less malleable at lower temperatures. Cold drop forging is often used for small – to – medium – sized parts made of materials that can withstand the high forces involved, such as certain grades of carbon steel.

Net Shape Drop Forging Process

The net shape drop forging process aims to produce a forging that is close to the final shape of the component, minimizing the need for subsequent machining. This process requires precise control of the forging parameters and the use of advanced dies. It can significantly reduce production costs by saving material and machining time, especially for parts where high precision is required.

Materials for Drop Forging

Carbon Steel Drop Forging Process

Carbon steel is a commonly used material in drop forging. It offers a good balance of strength, ductility, and cost – effectiveness. The carbon content in the steel affects its properties, with higher carbon content resulting in increased hardness and strength but reduced ductility. Carbon steel drop forging is suitable for a wide range of applications, from simple tools to automotive components.

Alloy Steel Drop Forging Process

Alloy steel, which contains additional alloying elements such as chromium, nickel, and molybdenum, is used when enhanced properties are required. Alloy steel drop forging can produce components with higher strength, corrosion resistance, and heat resistance. These properties make alloy steel – forged parts ideal for applications in the aerospace, military, and high – performance automotive industries.

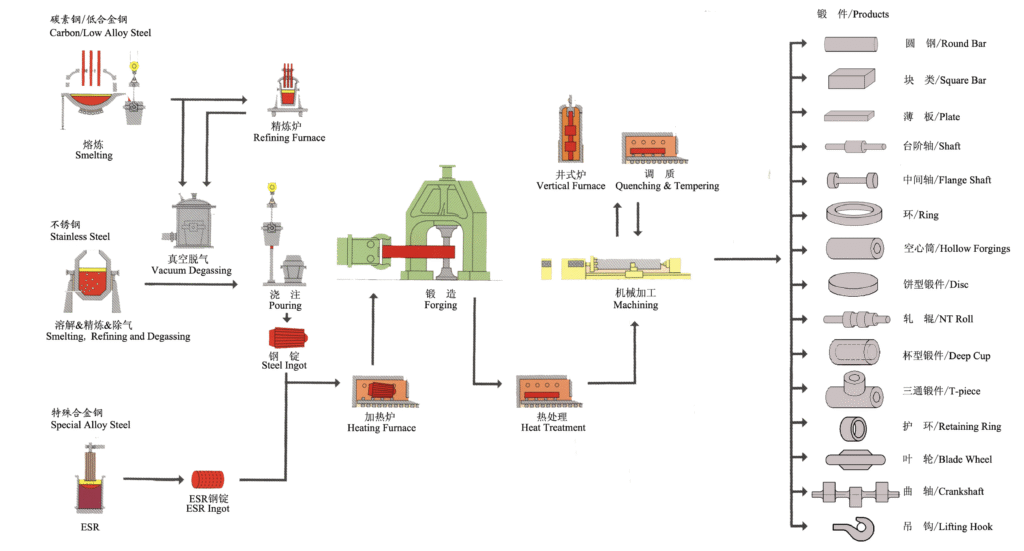

Leesh Foring Process

State-of-the-art manufacturing process ensuring highest quality standards

Hot Forging Materials We Use

High-quality steel materials for superior performance and durability

Carbon & Low Alloy Steel

35, 45, CK22N, Q235

16Mn, 20Mn2, 50Mn

20Cr, 40Cr

Structural Alloy Steel

20SiMn, 37SiMn2MoV

35CrMo, 42CrMo

34CrNiMo, 40CrNiMo

Specialty Steels

1Cr18Ni9Ti, 1Cr13

GH1, GH2, GH3, GH4 Series

F91, F92, 15Cr2MoV

Pressure Vessel Steel

09MnNiD, 16MnD

20MnMo, 15CrMo

ASME, GB Standards

Nuclear Power Steel

SA-182 Series

SA-266 Series

Nuclear Quality

Custom Materials

Tailored to Requirements

Full Material Analysis

Complete Traceability

Applications of Hot Forging

Net shape forging is widely used in industries requiring high-strength, precision components with minimal production costs. Below are the key application areas and typical components:

Automotive

- Connecting rods

- Crankshafts

- Gear blanks

- Steering components

- Suspension parts

Aerospace

- Turbine blades

- Engine brackets

- Landing gear components

- Hydraulic fittings

- Structural forgings

Energy

- Wind turbine shafts

- Power generator components

- Oil & gas valves

- Pipeline fittings

- Nuclear reactor parts

Heavy Machinery

- Excavator bucket teeth

- Bulldozer linkages

- Crane hooks

- Transmission gears

- Hydraulic cylinder rods