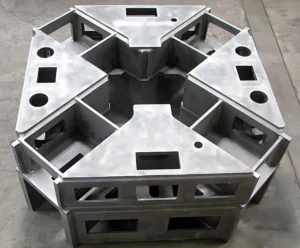

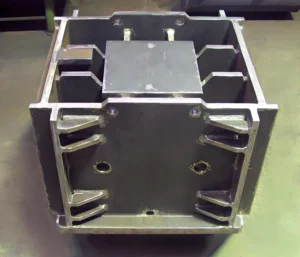

Our Fabrication Frame Weldment is a top-notch product for various applications.

The material used is ASTM A36, which has an equivalent grade of S235JR and Q235B. ASTM A36 is a carbon structural steel with good mechanical properties, welding performance and corrosion resistance. It has a yield strength of ≥250 MPa and tensile strength of ≥400 MPa.

The Powder Coated Finish not only enhances the aesthetic appeal but also provides excellent protection against corrosion and wear. It can withstand different environmental conditions, ensuring the longevity of the frame weldment.

This Fabrication Frame Weldment is widely used in construction, machinery manufacturing and other industries, offering reliable support and stability.

Steel Frame Weldment | Powder Coated Steel | ASTM A36 Material

- Sheet Metal Fabrication

- CNC Machining Services

- Industrial Metal Parts

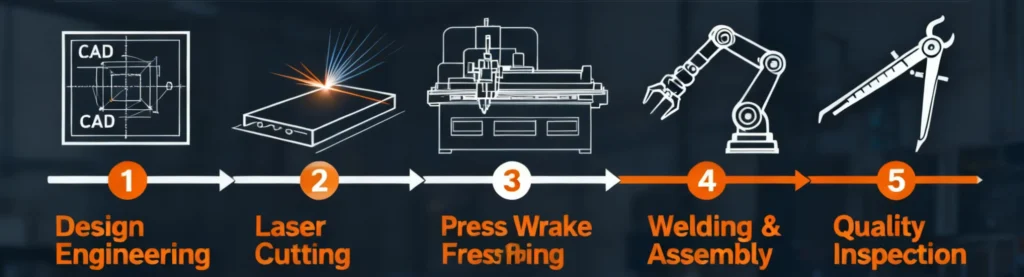

Leesh Metal Fabrication: Advanced Metal Processing Solutions

At Leesh Metal Fabrication, we leverage state-of-the-art equipment and precision engineering to deliver top-tier metal processing services. Explore our core capabilities through the machinery that powers our operations:

-

1. Fiber Laser Cutting

Our fiber laser cutting machine (seen below) represents the pinnacle of precision cutting technology. Equipped with advanced laser systems, it delivers:- High Precision: Tolerances as tight as ±0.05mm for complex geometries.

- Versatility: Cuts stainless steel, carbon steel, aluminum, and more, with thicknesses ranging from 0.5mm to 20mm.

- Efficiency: Rapid cutting speeds and minimal material waste, ideal for both prototyping and large-scale production.

2. Press Braking & Forming

We operate a range of press brakes to deliver accurate metal bending and forming:-

Conventional Press Brakes (second image): Reliable for medium-volume bending of sheet metal components, with bending forces up to 300 tons and lengths of 4 meters.

-

CNC Press Brakes (third image): Computer-controlled for ultra-precise bending, featuring multi-axis control, automated tool changing, and repeatability within ±0.02mm. Perfect for complex parts and high-volume orders.

3. Shearing

Our hydraulic shearing machine (fourth image) enables clean, straight cuts on sheet metal:- Handles materials up to 12mm thick and 3 meters wide.

- Features CNC-controlled back gauges for consistent, accurate cutting lengths.

Quality & Capability

Every machine in our facility is maintained to strict standards, ensuring:- Compliance with industry standards (ASTM, DIN, JIS).

- A dedicated team of engineers and technicians to oversee every project.

Contact us today to discuss your metal fabrication needs:- Email: info@leesh.cn

- Phone: +86 135 1608 5845