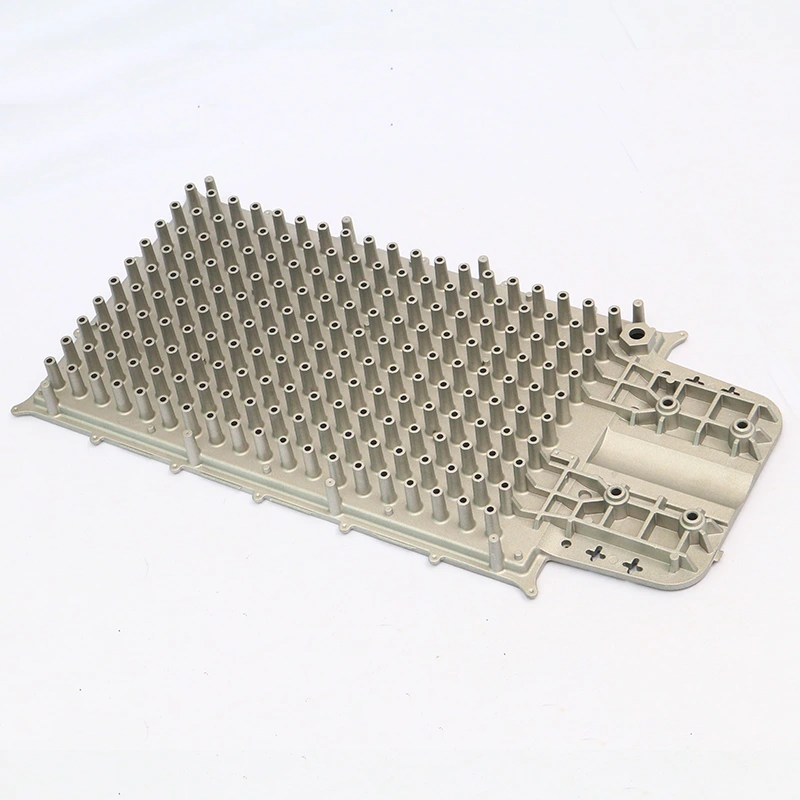

- Casting Method: Gravity Die Casting | Shell Mould Casting

-

Part Description: Heat Sink Plate

-

Class of Castings: Class Ⅱ

-

Casting Size: 772mm × 80mm

-

Material: AlSi5Cu3

-

Product Weight: 13.2kg

-

Maximum Wall Thickness: 8mm

-

Minimum Wall Thickness: 3mm

Gravity Die Casting is the Leesh key manufacturing process for producing high-quality aluminum components. For the AlSi5Cu3 (EN AC-45400) alloy, this method is the perfect process for complex Automotive Components like cylinder heads and engine housings. By relying on natural gravitational force rather than high-pressure injection, the process ensures a more uniform Solidification Rate, resulting in a dense and reliable internal structure.

Superior Material Integrity with Gravity Die Casting

Also known as Permanent Mold Casting, this technique uses reusable steel or iron molds to achieve higher tolerances and smoother surface finishes than traditional sand casting. The high silicon content in AlSi5Cu3 provides excellent Castability, allowing the molten metal to flow seamlessly into intricate mold geometries. To ensure the highest quality, our process includes Degassing and Fluxing steps to eliminate hydrogen gas and non-metallic inclusions before the pour.

Optimized Mechanical Properties via T6 Heat Treatment

To unlock the full potential of AlSi5Cu3, our castings always take T6 Heat Treatment. This thermal process—consisting of solutionizing and artificial aging—transforms the microstructure by managing Intermetallic Phases. This results in a significant boost to the material’s Tensile Strength (UTS) and hardness. Whether you require lightweight solutions or heavy-duty industrial parts, our gravity-fed processes deliver the precision and strength your project demands.

| Manufacturing Method | Die Casting Services |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 Aluminum alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063, AlSi9Cu 2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 Magnesium alloy: AZ91D, AM60B, 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 Zinc alloy: ZA3#,ZA5#,ZA8# |

| Weight Range | 3g – 20 kgs |

| Dimension Range | Mini 80 X 80 mm, Max 800 X 800 mm |

| Tolerance | ±0.02mm |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Ultimate machining tolerance | 0.005mm |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Finish Roughness | Ra0.8-Ra1.6 according to customer requirement |

| Heat Treatment | Normalization , Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |