- Steering Knuckle Arms

- Forged Steering Components

- Automotive Knuckle Arms

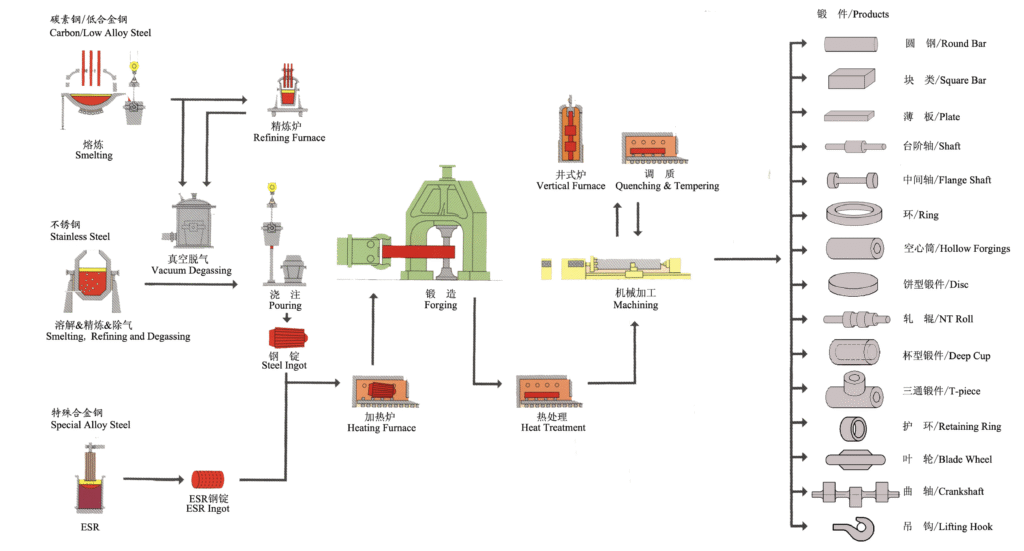

Our forged knuckle arms are produced using high-quality alloy steel through a rigorous forging process that includes heating, shaping, heat treatment, and precision machining. This manufacturing method ensures superior strength, durability, and dimensional accuracy, making them ideal for use in automotive steering systems. The forging process enhances the material properties, providing excellent resistance to wear, fatigue, and impact loads in demanding operating environments

| General Process | Heating->Preforming->Finish Forging->Cooling->Finishing |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc Duplex stainless steel 1.4462,F51,S31803,F60,S32205,F53,S32750 Alloy steel F1,F5,F9,F11,4130,4140,8620,42CrMo4,34CrNiMo6, Carbon steel ASTM A105,ASTM A350,ASTM A694,F42,F50,F60,F65,F70,S355J2G3,18CrNiMo7-6, etc Hastelloy Inconel 625 Monel K500 |

| Max.Weight | 30 Tons |

| General Tolerance | Customized |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Ultimate machining tolerance | 0.005mm |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Finish Roughness | Ra3.2-Ra12.50 according to customer requirement |

| Heat Treatment | Normalization , Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |