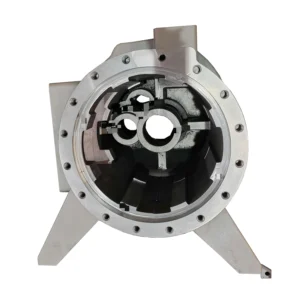

Leesh: Your Premier Resin Coated Sand Casting Partner

Key Processes in Resin Coated Sand Casting

Shell Molding

Shell molding is a cornerstone of our resin coated sand casting operations. By applying a resin – coated sand mixture around a heated pattern, we create a thin, hardened shell. This shell offers exceptional dimensional accuracy, making it perfect for intricate castings. Whether for standard applications or those demanding unique materials as per customer requests, shell molding ensures precision.

Hot Box Process

The hot box process is another integral part of our offerings. In this method, resin – coated sand cores are cured in a heated box. This results in cores with high strength, enhancing the overall quality of the casting. It plays a crucial role in our molding & core – making procedures, enabling us to meet diverse customer needs.

Molding & Core Making

| Manufacturing Method | Sand Casting(Resin Sand, Pre-Coated Sand, Clay Sand, Water glass sand, Green Sand,lost foam ) |

| Material Standard | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc carbon steel, low carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc. Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, etc. Stainless Steel: SUS 304, 304L, 316, 316L, CF8, CF8M, G-X7CrNiNb1189, etc. AS2074 or according to customer specific requirement. Ductile Iron:A536-Gr.60-40-18,GGG40,GGG50,FCD40,FCD50,Gr370-17,Gr420-12,etc Grey Iron:A48-No.20,25,30,GG10,GG15,GG20,FC10,FC15,FC20,Grade 150,180,220,FGL150,FGL200,FGL250,etc |

| Weight Range | 1 kg to 100 Tons |

| General Casting Tolerance | CT8-CT12 |

| Design Software | UG, Pro-E, Inventor |

| Dwg Format | STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT |

| Mould Manufacturing | Yes |

| Casting Stimulation | Yes |

| Ultimate machining tolerance | 0.005mm |

| Quality Control | RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc |

| Finish Roughness | Ra12.5-Ra25 according to customer requirement |

| Logo/ID | Silk-screening, Laser Marking, Engrave,Painting |

| Heat Treatment | Normalization, Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc |