20 August, 2025

C86500 Is a kind of copper alloy material, mainly used in chemical machinery and equipment, with high electrical conductivity, thermal conductivity, corrosion...

20 August, 2025

Size ange (mm)

CT Category

From

To

3

4

5

6

7

8

9

10.00

0.18

0.26

0.36

0.52

0.74

1.00

10.00

1.50

16.00

0.20

0.28

0.38

0.54

0.78

1.10

16.00

1.60

25.00

0.22

0.30

0.42

0.58

0.82

1.20

25.00

1.70

40.00

0.24

0.30

0.46

0.64

0.90

1.30

40.00

1.80

63.00

0.26

0.36

0.50

0.70

1.00

1.40

63.00

2.00

100.00

0.28

0.40

0.56

0.78

1.10

1.60

100.00

2.20

160.00

0.30

0.44

0.62

0.88

1.20

1.80

160.00

2.50

250.00

0.34

0.50

0.70

1.00

1.40

2.00

250.00

2.80

400.00

0.40

0.56

0.78

1.10

1.60

2.20

400.00

3.20

630.00

–

0.64

0.90

1.20

1.80

2.60

630.00

3.60

1,000.00

–

–

1.00

1.40

2.00

2.80

1,000.00

4.00

NOTES:

1....

20 August, 2025

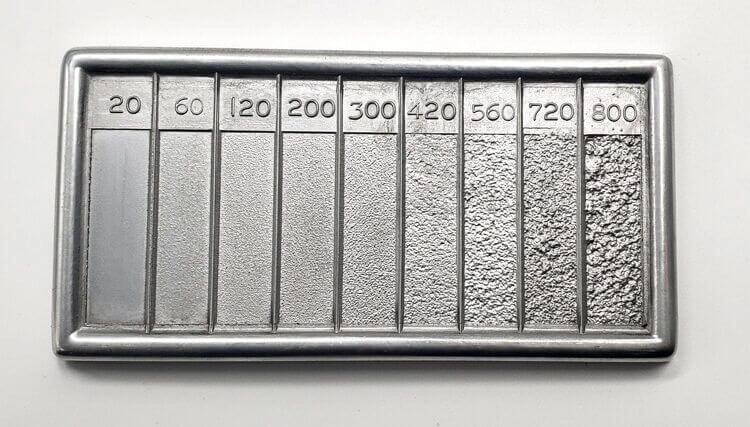

1-Smooth surface finish

Use the Aluminum mould and wax to make the pattern, then glue with the silica sol as binding agent, so you will see a very clear...

20 August, 2025

Knowing the surface roughness by different manufacturing method- it will let you make the right decision to choose the best suitable method and material,...

20 August, 2025

Country

Standard

Equivalent Grades of Grey Iron (Gray Cast Iron)

ISO

ISO 185

100

150

200

250

300

350

–

China

GB 9439

HT100

HT150

HT200

HT250

HT300

HT350

–

USA

ASTM...

18 August, 2025

High Frequency Induction Quenching is a form of heat treatment in which a metal part, High Frequency Induction Quenching is heated by induction heating...

18 August, 2025

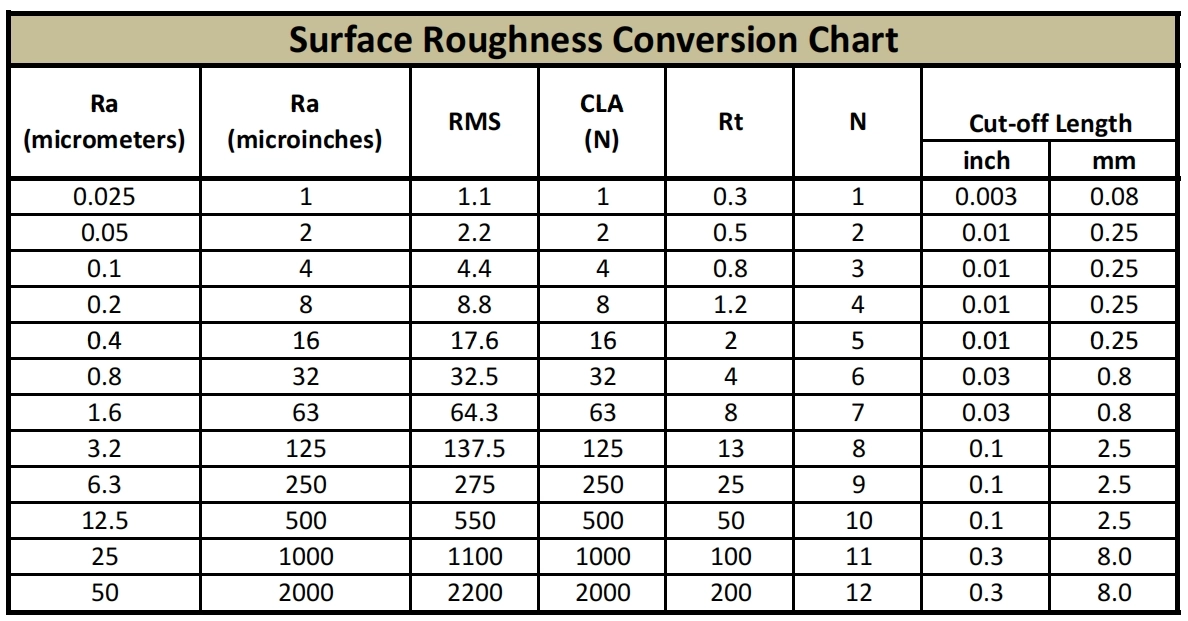

There is a table below shows the comparisons of various surface roughness scales. The information contained in the table is based on the assumption that...

18 August, 2025

Leesh Silica sol precision casting (also known as investment casting or lost-wax casting) is built on advanced equipment, mature techniques, and extensive...

18 August, 2025

Leesh and China Textile Machinery Group have singed first 10 Tons Textile Machinery parts (Investment Casting) contract at the Liaoning Mansion Hotel.

18 August, 2025

1. Process Principles Comparison

Process

Pressure Source

Filling Method

Typical Pressure Range

High Pressure Casting (HPDC)

Hydraulic or mechanical...

No posts found