1-Smooth surface finish

Use the Aluminum mould and wax to make the pattern, then glue with the silica sol as binding agent, so you will see a very clear difference compare with Sand Casting .Mostly the roughness range from Ra 1.6 μm to Ra6.4 μm, but Leesh Engineering Investment Casting service can achieve a average above 3.2μm.

2-Save machining Time and Cost

In many condition- because the smooth surface finish- you don’t need to do the machining for assembly compare with our manufacturing methods. If you really want to do the machining– the machining allowance don’t not need as much as sand casting

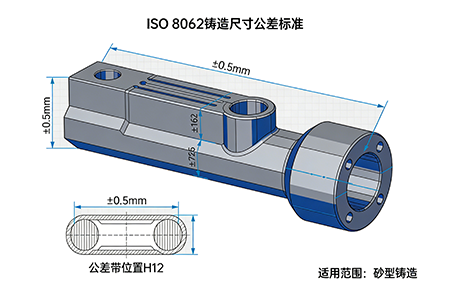

3-High Tolerance control

The general casting tolerance is CT4-CT7, which is not necessary to do machining job in many application. Mostly just drill and tap should be fine.

4-Integrated Shape

It can make more complicate and complex shape, which is the fabrication can’t compare.

In traditional way- you have to make more than 2 parts , then make the assemble, but investment casting can achieve a integrated shape through one time cast

5-Vast Size and weight range

We can make few grams to dozens of kilograms weight

And few centimeters to Ø800mm meters size range

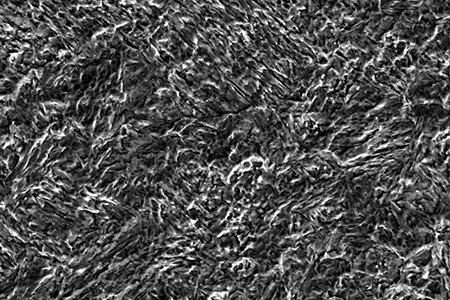

6-Consistency

Once the mould made- the casting has the best consistency of quality and shape.compare with other manufacturing method- it less people operation, easy metal running system, so it easy to avoid the porosity , gas holes, ect casting defects

Leesh Engineering has the best experienced engineering team and high automatic production line, if you have any investment casting service need, please feel free contact our casting expert sales@leesh.cn,

Thanks.