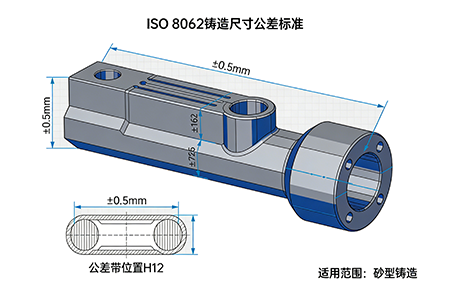

Manual moulding

Manual moulding refers to the moulding process of using hand or hand tools to complete the main operations such as place tooling, compact and press sand to tight, remove tooling, place core box and adding gating system. The manual molding operation is flexible, the process equipment such as tooling and core box is simple, the production preparation time is short, the tooling cost is low, and the adaptability to the size and structure of the casting is wide. However, the quality of hand-molded castings can’t compare with machining moulding, the productivity is low, the labor intensity is high, and the technical level is high. Therefore, manual moulding is mainly used in single piece, small batch production, especially heavy complex castings.

Machine Moulding

Machine moulding Machine moulding is a moulding method that mechanizes the two most important operations in the moulding process – sand compact and tooling remove. Compared with manual moulding, machine moulding and core production productivity is high, the productivity of the molding machine can reach 30~80 boxes/hour, or even hundreds of boxes per hour; Machine casting size accurate, smooth surface, stable quality: low labor intensity of workers. However, the cost of equipment and process equipment is high, and the production preparation cycle is long, which is suitable for mass and batch production of castings. The machine molding can be combined with the mechanized sand mixing, sand adding and mechanized casting, sand dropping, cleaning, transportation and other processes before moulding to form mechanized automatic production lines to further improve production efficiency.