Heat Treatment Training Seminar

1. Basic Knowledge of Heat Treatment

1.1 What is Heat Treatment? Why Do Parts Need Heat Treatment?

- Heat Treatment: A process involving heating, holding, and cooling metal materials.

- Purpose: Adjust the internal structure of materials to obtain desired properties (e.g., strength, hardness, toughness).

1.2 Common Heat Treatment Processes

1) Quenching and Tempering

- Quenching: Heat steel above the transformation point and cool it in a quenching medium.

- Tempering: Heat quenched steel to a specific temperature, hold it, and then cool.

- Note: Generally refers to quenching plus low-temperature tempering.

2) Modulation Treatment

- Process: Heat steel to 30~50℃ above Ac3 (hypoeutectoid steel) or Ac1 (hypereutectoid steel), hold for a certain time, and cool rapidly at a rate exceeding the critical cooling rate. Followed by high-temperature tempering to improve toughness.

- Application: Most parts requiring good comprehensive mechanical properties.

- Arrangement: Usually performed after rough machining.

3) Annealing

A process of heating steel or steel parts to an appropriate temperature, holding, and then cooling slowly. Common types:

| Type of Annealing | Process | Purpose | Arrangement |

|---|---|---|---|

| Full Annealing | Heat to 30~50℃ above Ac3, hold, and furnace-cool | Refine grains, reduce hardness, improve plasticity, eliminate internal stress | After casting or forging |

| Stress Relief Annealing | Heat to appropriate temperature, hold, and cool slowly | Eliminate residual stress from processing/welding/casting | After welding, rough machining, or semi-finishing |

| Spheroidizing Annealing | Heat to 20~30℃ above Ac1, hold, and furnace-cool | Reduce hardness for machining, improve comprehensive properties | After casting or forging (for tool steel, bearing steel, high-carbon steel) |

4) Normalizing

- Process: Heat steel to 30~50℃ above Ac3 (hypoeutectoid steel) or Accm (hypereutectoid steel), hold, and cool in still air outside the furnace.

- Arrangement: Usually after casting or forging; occasionally after rough machining for special cases.

5) Solution Treatment

- Process: Heat alloy to the high-temperature single-phase region, hold to fully dissolve excess phases into the solid solution, and then cool rapidly to obtain a supersaturated solid solution. Also known as "solution quenching."

- Application: Commonly used for austenitic stainless steel.

6) Spray Quenching

- Application: Large work rolls and supporting rollers requiring high surface hardness. Heat to quenching temperature and cool by spraying.

7) Full Quenching

- Process: Heat steel above the critical point, cool in a quenching medium, and then temper at low temperature.

- Application: Small parts requiring high hardness, large parts requiring high strength (e.g., backup rolls), and supporting wheels with high surface hardness and low inner hole hardness.

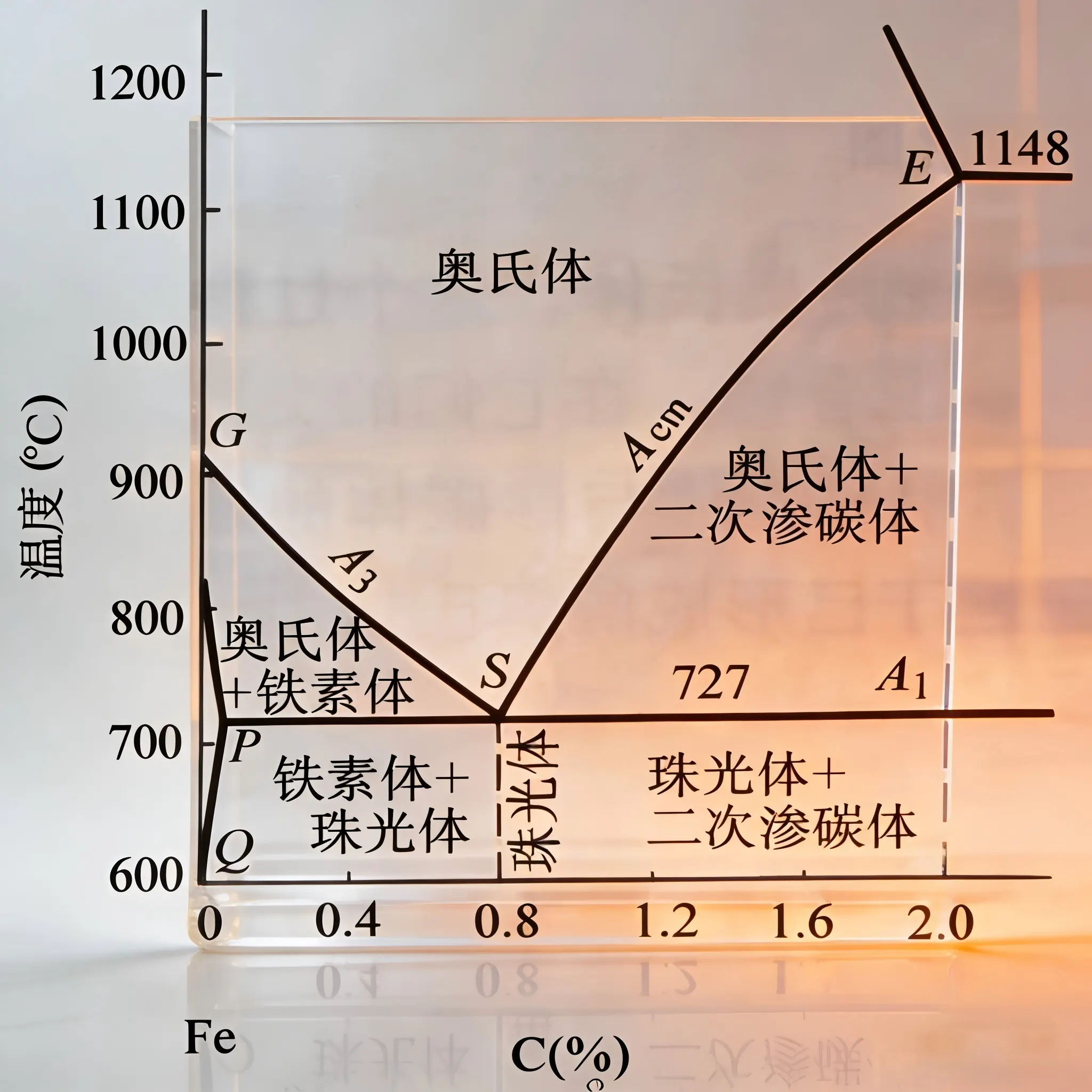

1.3 Simplified Fe-Fe₃C Phase Diagram

The iron-carbon equilibrium diagram is the foundation for studying steel heat treatment processes.

Figure: Simplified Fe-Fe₃C Phase Diagram

1.4 Microstructural Transformation of Steel During Heating

- At room temperature, the structure of balanced steel varies with carbon content.

- When heated to Ac1: Pearlite in eutectoid steel transforms to austenite; ferrite in hypoeutectoid steel and secondary cementite in hypereutectoid steel remain.

- Continue heating to Ac3 (hypoeutectoid steel) or Accm (hypereutectoid steel): Complete austenitization is achieved.

- Austenite Formation Stages: Nucleation → Growth → Dissolution of residual cementite → Homogenization of austenite composition.

1.5 Microstructural Transformation of Steel During Cooling

The cooling method and rate after austenitization are decisive factors affecting the final structure and properties of steel. Different cooling conditions result in significantly different structures and properties.

1.6 Hardenability, Hardening Capacity, and Role of Alloying Elements

1) Hardenability

- The ability of steel to obtain a hardened layer during quenching.

- Hardened Layer Depth: Depth from the part surface to the half-martensite zone.

2) Hardening Capacity

- The maximum hardness achievable by steel after quenching.

3) Role of Alloying Elements

| Element | Effect |

|---|---|

| Carbon | 0.25~0.5% in modulated steel; increases strength, hardness, and wear resistance but reduces plasticity and toughness. |

| Nickel | Weakly improves hardenability alone; significantly enhances hardenability when combined with chromium. |

| Chromium | Significantly improves hardenability and tempering stability when dissolved in austenite. |

| Molybdenum | Significantly improves hardenability and tempering stability; prevents secondary temper brittleness caused by Mn, Cr, Ni. |

| Manganese (Impurity) | Below 0.8%, improves processability, strength, and hardness; reduces sulfur damage; increases hardenability but promotes austenite grain growth. |

| Silicon (Impurity) | Below 0.37%, minimal effect; slightly increases σs and σb with higher content. |

| Sulfur (Harmful Impurity) | Causes chemical inhomogeneity and non-metallic inclusions; improves machinability but is detrimental to toughness. |

| Phosphorus (Harmful Impurity) | Increases strength and hardness but drastically reduces plasticity and toughness (severe at low temperatures); improves machinability. |

1.7 Influence of Quenching Media on Properties

Common quenching media: water (highest cooling capacity), oil (lower cooling capacity than water), and intermittent cooling (water-air, water-oil, oil-air).

| Cooling Resulting Structure | Mechanical Properties After Tempering |

|---|---|

| Martensite | Hardness/strength decreases; plasticity/toughness increases with tempering temperature. |

| Lower Bainite | Similar to tempered martensite at the same temperature; higher impact toughness. |

| Upper Bainite/Pearlite | Low strength and poor plasticity; inferior comprehensive mechanical properties. |

| Ferrite | Significantly degraded comprehensive mechanical properties, especially impact toughness. |

1.8 Influence of Tempering Temperature on Properties

1) Tempering of Martensite

- Transformations: Decomposition of martensite, transformation of retained austenite, recovery/recrystallization of α-phase, and precipitation/growth of carbides.

- Hardness decreases with increasing tempering temperature due to carbide precipitation.

2) Tempering of Pearlitic Initial Structure

- Carbide aggregates and spheroidizes; larger spheroidal pearlite forms at higher temperatures, improving comprehensive properties.

3) Tempering of Bainite

- Fine carbides in bainite spheroidize at low temperatures; hardness/strength decrease, and plasticity/toughness increase.

1.9 Quenching Deformation and Cracking

1) Quenching Internal Stress

The root cause of deformation and cracking. Two types of stress:

- Thermal Stress: Caused by uneven thermal expansion/contraction due to temperature differences between surface and core.

- Heating: Surface (compressive stress), core (tensile stress)

- Cooling: Surface (tensile stress), core (compressive stress)

- Structural Stress: Caused by uneven volume changes during phase transformation. Volume order (from large to small): Martensite → Tempered Martensite → Lower Bainite → Troostite → Sorbite → Pearlite → Austenite.

2) Methods to Reduce Deformation

- Eliminate stress before heat treatment.

- Rational furnace loading, heating, and cooling methods.

- Proper quenching operation.

3) Methods to Prevent Cracking

- Strictly control raw material quality.

- Rational part structure design.

- Select appropriate quenching media and slow cooling in the martensite zone.

- Temper immediately after quenching.

2. Properties of Metal Materials

Metal material properties are divided into service properties and processing properties.

2.1 Service Properties

Properties required during service, including physical, chemical, and mechanical properties. Focus on mechanical properties:

| Mechanical Property | Definition & Symbol |

|---|---|

| Strength | Resistance to permanent deformation and fracture. - Tensile strength (σb) - Yield strength (σs: stress at 0.2% plastic deformation) |

| Plasticity | Ability to deform without fracture. - Elongation (δ) - Reduction of area (ψ) |

| Hardness | Resistance to local deformation. - Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL) |

| Toughness | Resistance to impact loading. - U-notch impact energy (Aku) - V-notch impact energy (Akv) |

| Fatigue Strength | Resistance to cracking/fracture under cyclic loading. |

| Wear Resistance | Resistance to wear (critical for gears, liners, etc.). |

2.2 Processing Properties

Properties during processing, including casting, forging, heat treatment, welding, and machining properties. These properties guide the formulation of cold/hot processing processes (e.g., fluidity, formability).

3. Applications of Heat Treatment Process Products

3.1 Annealing

1) Purpose

- Reduce hardness.

- Eliminate post-forging structural defects.

- Prepare structure for subsequent heat treatment.

- Eliminate stress.

2) Selection Principles

- Hypoeutectoid steel: Full annealing (isothermal annealing for time saving).

- Eutectoid/hypereutectoid steel: Spheroidizing annealing (for tool steel, bearing steel, high-carbon steel) or incomplete annealing.

- Stress relief: Stress relief annealing.

3) Notes

Attention: For stress relief processes with small part allowances:

1) Ensure flat and stable furnace loading;

2) Protect parts with small allowances;

3) Heat and cool slowly.

3.2 Normalizing

1) Purpose

- Refine grains.

- Improve properties (can be used as final heat treatment for some parts).

- Prepare structure for subsequent heat treatment.

- Eliminate initial structural defects.

2) Applications

| Steel Type | Application Purpose |

|---|---|

| Low-carbon Steel | Improve machinability and avoid tool sticking. |

| Medium-carbon Steel | Final heat treatment for low-performance requirements (especially large castings). |

| High-carbon Steel | Improve carbide morphology for subsequent heat treatment. |

| Steel with Coarse Grains/Defects | Grain refinement; substitute for modulation in large carburized parts. |

3.3 Quenching and Tempering

1) Quenching Temperature Selection

- Hypoeutectoid steel: 30~50℃ above Ac3.

- Eutectoid/hypereutectoid steel: 30~50℃ above Ac1 (retain partial carbides for higher hardness and wear resistance).

2) Quenching Media

| Quenching Medium | Characteristics & Applications |

|---|---|

| Water | Common and low-cost; limited applicability. |

| Oil (20# Machine Oil) | Lower cooling capacity than water; used for alloy steel and large carbon steel. |

| Quenchants | Synthetic polymers; cooling capacity between water and oil. |

| Water-Oil Cooling | Water cooling at high temperature, then oil cooling; reduces cracking risk. |

| Water-Air-Water Cooling | Intermittent cooling; avoids cracking from prolonged water cooling. |

3) Quenching Defects

Common defects: Thermal/structural stress, deformation, cracking. Influencing factors include chemical composition, initial structure, part geometry, design, and process operation.

4) Tempering

Classified by temperature:

| Tempering Temperature | Formed Structure |

|---|---|

| 150~250℃ (Low-temperature) | Tempered Martensite |

| 350~450℃ (Medium-temperature) | Tempered Troostite |

| 500~650℃ (High-temperature) | Tempered Sorbite |

| 650~A1℃ | Tempered Pearlite |

4. Factors Affecting Heat Treatment Quality

Heat treatment quality is a comprehensive reflection of the entire design and manufacturing process, influenced by multiple factors:

4.1 Rational Design and Material Selection

- Select materials based on load, working conditions, and failure modes (e.g., 38CrMoAl for nitriding, 20CrMnTi for carburizing).

- Design parts with uniform cross-sections, rounded corners, and minimal holes/grooves to avoid stress concentration.

- Set realistic heat treatment requirements matching material potential.

4.2 Excellent Metallurgical Quality

- Metallurgical Processes: Steelmaking, casting, and forging defects (non-metallic inclusions, white spots, banded structures) cannot be eliminated by heat treatment and may cause distortion or cracking.

- Chemical Composition: Determines microstructure and properties; strictly inspect raw materials for chemical composition, macrostructure, microstructure, and mechanical properties.

4.3 Process Parameters and Operation

- Proper selection of heating temperature, holding time, and cooling rate.

- Standardized operation (furnace loading, quenching, tempering).