Common Defects in Castings

During many years’ practical experience, the Leesh engineer team has made notes on common casting defects, helping people understand them better and try to avoid them.

Casting defects cannot disappear completely, but you can control them by using better casting methods and strict process control.

If you have any issue during the produciton, we are happy to share our knowledge and study together, our engineer contact david.lee@leesh.cn

or Contact Us | China Casting Foundry – Global Casting Experts (chinafoundrygroup.com)

| Name | Image | Description |

|---|---|---|

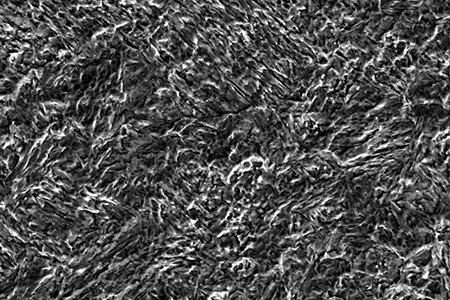

| Sand Inclusion |  |

There are holes filled with molding sand on the surface or inside the casting. |

| Blowhole |  |

There are smooth holes of varying sizes inside, on the surface, or near the surface of the casting. They are generally spherical or approximately spherical clustered holes with smooth walls. |

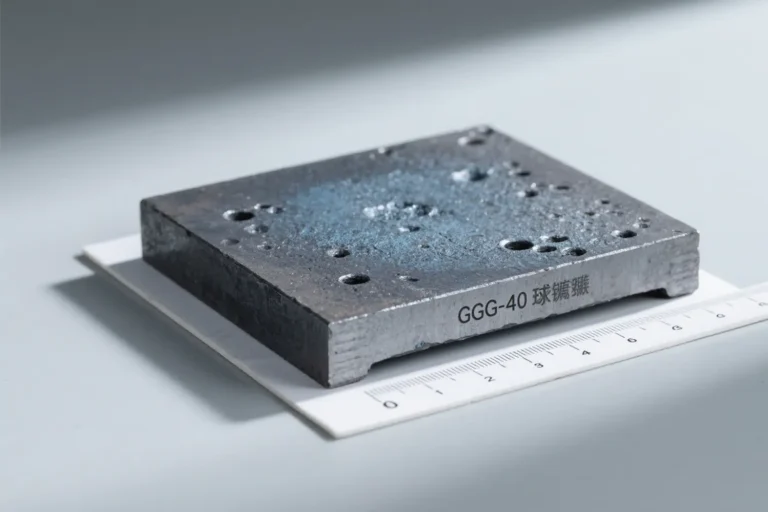

| Shrinkage Cavity |  |

It is an irregular closed or exposed hole with rough walls and dendrite-like structures. It often appears in the last solidified part (hot spot) of the casting. |

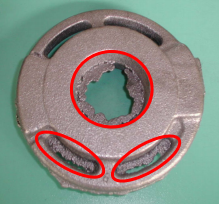

| Flash |  |

Flash refers to uneven flaky metal protrusions on the casting surface, usually appearing at the parting surface and core print of the casting. |

| Burr |  |

Burrs are sharp metal protrusions on the casting surface, often found at the cracks of the mold and core, with extremely irregular shapes. |

| Misrun |  |

It is a lack of metal in the casting caused by the molten metal failing to fully fill the mold cavity. |

| Name | Image | Description |

|---|---|---|

| Sand Adhesion |  |

The entire or partial surface of the casting is covered with a mixture of metal and sand, or a layer of sintered molding sand, resulting in a rough casting surface. |

| Cold Shut |  |

A cold shut is an incompletely fused gap or depression on the casting, with rounded edges at the junction. It often appears on the wide upper surface and thin-walled parts of the casting far from the gate, at the confluence of molten metal streams, or in chilled areas. |

| Sand Wash |  |

There are rough and irregular metal nodules on the casting surface, usually near the gate. Sand inclusions often appear in other parts of the casting. |

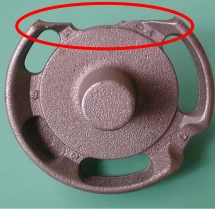

| Sand Drop |  |

It is a massive metal protrusion on the casting surface, whose shape is very similar to the dropped sand block. Sand inclusions or defects often appear in other parts of the casting. |

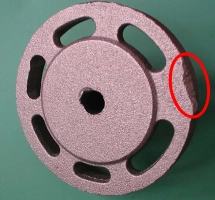

| Damage |  |

The integrity of the casting is damaged during cleaning or handling. |

| Deformation |  |

The shape and size of the casting do not conform to the drawing due to shrinkage stress, mold wall deformation, or cracking. |