GGG40 is a ductile iron grade of Germany standard, which is similar to QT400, ASTM A536 60-40-18, 60-40-15, FCD400, GS400-12, FGS400-12, 400/17, 420/12, 400-12, 400-18 and SG38, SG40.

| Grades | Tensile Strength (Mpa) | Elongation (%) | Impact Resistance (J) |

| EN-GJS-400-15 | ≥ 400 | ≥ 15 | Not Specified |

| EN-GJS-400-18 | ≥ 400 | ≥ 18 | Not Specified |

| EN-GJS-400-18LT | ≥ 400 | ≥ 18 | 12J at -20°C |

The Application of GGG40

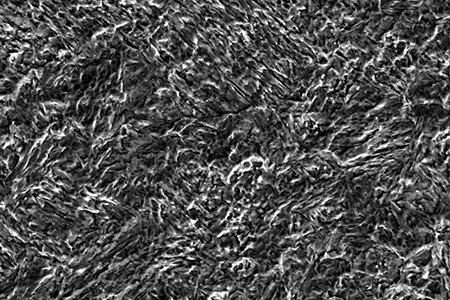

GGG40 is a very good material grade of ductile iron, which has good tensile strength and yield strength, and especially very high elongation rate. The higher grade will mean the lower elongation, so GGG40 has the highest elongation rate in all ductile iron grades.

This material is suitable for many industrial and civil fields. Such as automotive castings, truck and agricultural parts, various machinery casting parts, manhole covers, even for pump and valve parts.

We can produce OEM iron casting parts, strictly in according with your drawing or samples. 100% meet the requirements of the designer.

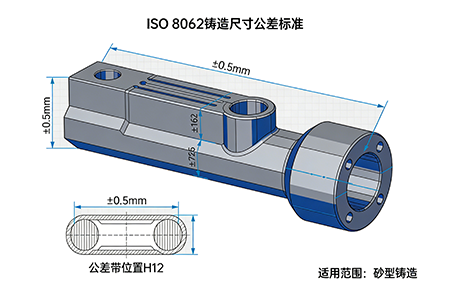

| 1.Product | Iron Sand Casting Parts |

| 2.Material | ductile iron, grey iron, HT200, HT250, QT450-10 QT500-7. |

| 3. Machine | Resin sand manual molding, lost foam production line,CNC Horizontal Lathe, CNC Vertical Lathe, CNC Gantry Milling, Vertical and Horizontal machining Center |

| 4.Process | Drawings & Samples, Tooling design, Tooling make, Cast, Deburring, CNC machining, Surface treatment, Quality inspection, Packing, Shipping. |

| 5. machining | Turning, Milling, Reaming, Boring, Tapping etc. |

| 6.Finish | Custom make as per your requirement, such as painting, powder coating, galvanization etc. |

| 7.Test Equipment | CMM, optical spectrum instrument, dial caliper, altimeter, all kinds of gauge etc. |

| 7.Drawing File | PDF, IGS, STEP, STP, CAD. |

| 8.Our Advantage | Delivery fast!We will refund the tooling cost after your order quantity reach to a certain volume. |

This material suite to Sand Casting process,if you have any parts of this kind material please feel free send email to sales@leesh.cn, thanks.