Leesh, a prominent player in the global foundry industry with decades of specialized experience, offers comprehensive gravity die casting (GDC) services enhanced with specialized T6 heat treatment processes. As a member of China Foundry Group, Leesh has established itself as a trusted provider of high-quality metal components, serving diverse industrial sectors worldwide.

With state-of-the-art facilities and a team of highly skilled engineers, Leesh combines traditional casting expertise with cutting-edge technology to meet the most demanding requirements of global customers. The company’s gravity die casting T6 treatment represents the pinnacle of its manufacturing capabilities, delivering components that excel in both performance and reliability.

Caption: Advanced gravity die casting facility with modern equipment

What is Gravity Die Casting?

Gravity Die Casting, also known as permanent mold casting, is a sophisticated manufacturing process where molten metal flows into a permanent mold cavity by its own gravity, solidifies upon cooling, and forms the desired casting.

Core Principles and Features

- Simple mold structure with open or semi-open runner designs

- Slow filling speed ensuring stable molten metal flow

- Reduced internal defects such as pores and shrinkage cavities

- Moderate casting density with excellent mechanical properties

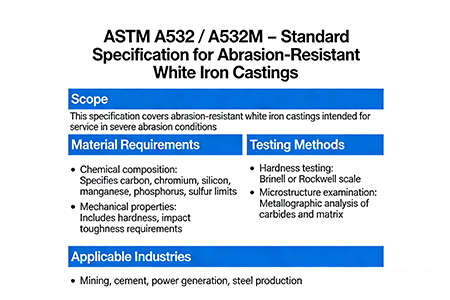

Material Compatibility

Leesh’s gravity die casting capabilities cover a wide range of materials:

- Aluminum alloys: ZL104, A356, A360, A413

- Magnesium alloys: AZ91D, AM60B

- Copper alloys

- Cast iron

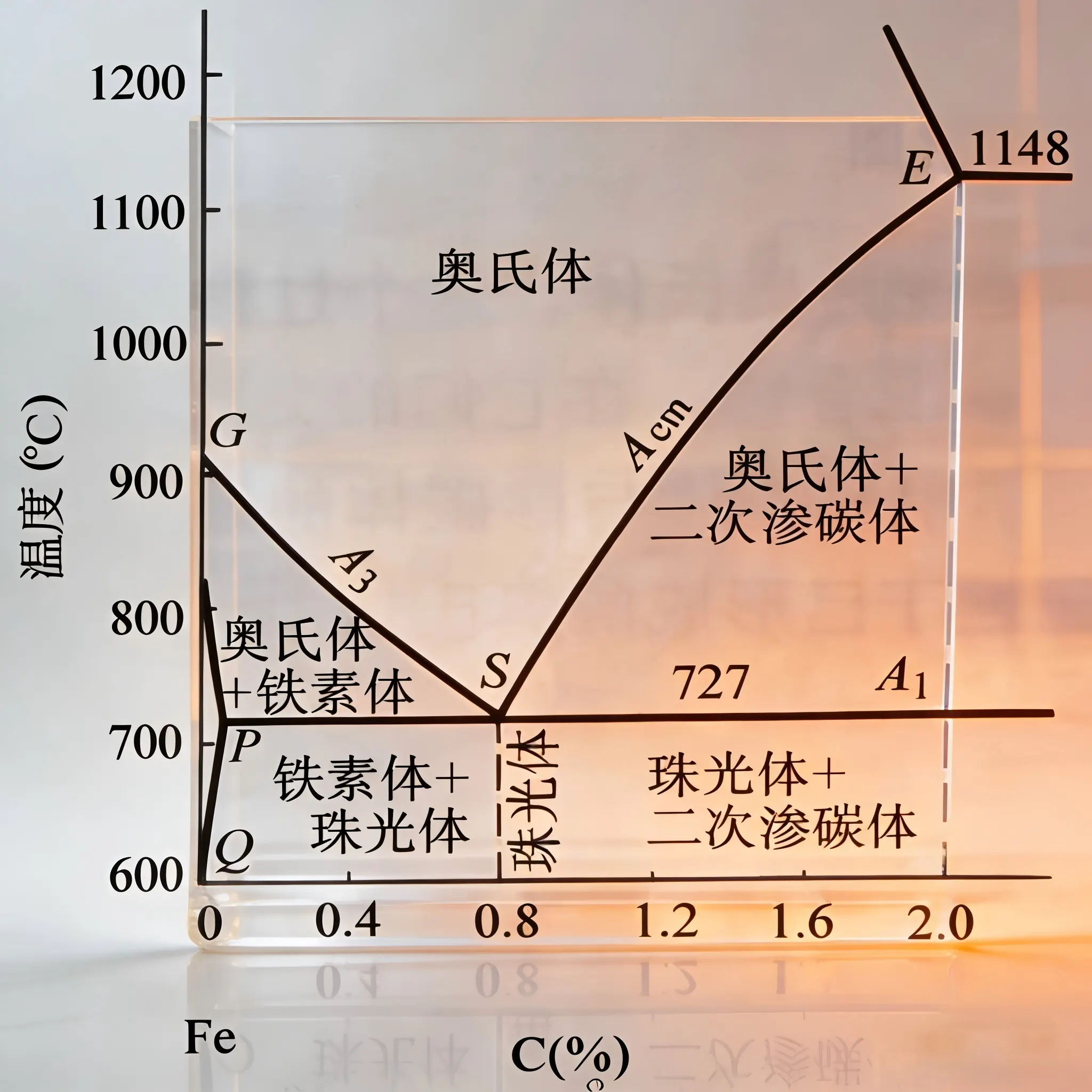

The T6 Heat Treatment Advantage

Leesh’s T6 heat treatment process transforms standard cast components into high-performance engineering parts through a sophisticated three-stage thermal processing.

Advanced T6 Treatment Process

- Solution Heat Treatment: Precise heating to 530-540°C for aluminum alloys to dissolve alloying elements

- Rapid Quenching: Controlled cooling to retain the homogeneous solution structure

- Artificial Aging: Carefully controlled heating at 120-180°C to precipitate fine strengthening phases

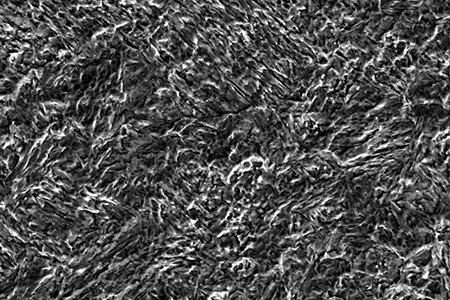

Performance Enhancements

- 30-50% improvement in tensile strength

- Up to 60% increase in yield strength with excellent ductility

- Hardness enhancement from 60-70 HB to 90-110 HB

- Superior corrosion resistance exceeding 96-hour salt spray test

- Exceptional fatigue life and impact resistance

- Outstanding dimensional stability with minimal distortion

Caption: Specialized T6 aluminum alloy aging furnace for heat treatment

Key Advantages of Leesh’s GDC T6 Process

Cost-Effectiveness

- Low mold manufacturing costs compared to other casting methods

- Long mold service life (thousands to tens of thousands of parts)

- Reduced scrap rates and material waste

Production Efficiency

- Easy production control with low operational thresholds

- Suitable for small to medium batch production requirements

- Moderate cycle times (1-5 minutes per part)

Quality Assurance

- High casting density (95%-97%)

- Excellent surface finish with Ra 6.3-25μm

- Precise dimensional control (IT12-IT14 tolerance range)

Applications Across Industries

Leesh’s gravity die casting T6 treatment finds applications across diverse industries:

Mechanical Engineering

- Gearbox housings and transmission components

- Structural brackets and machine bases

- Valve bodies and pump casings

Automotive Industry

- Engine brackets and mounting components

- Wheel blanks and suspension parts

- Critical mechanical assemblies

General Machinery

- Hydraulic system components

- Pneumatic equipment parts

- Industrial machinery housings

Caption: Precision aluminum casting components manufactured using GDC T6 process

Quality Control Excellence

Leesh maintains rigorous quality standards throughout the manufacturing process:

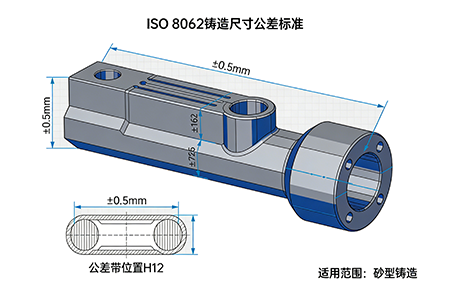

Dimensional Tolerance

- Precise dimensional control with ±0.02mm tolerance range

- Flatness within 0.1mm after machining

- Surface roughness Ra1.6 after finishing operations

Surface Treatment Options

- Electroplating: Chrome, Zinc, Nickel

- Chemical treatments: Anodization, Passivation

- Physical finishing: Polishing, Sandblasting

- Powder coating and electrostatic spraying

Testing and Inspection

- 100% inspection on critical dimensions and appearance

- Advanced testing facilities including CMM, X-ray flaw detection

- Salt spray testing and material composition analysis

Why Choose Leesh for Your GDC T6 Needs

Technical Expertise

- Decades of experience in gravity die casting technology

- Specialized knowledge in T6 heat treatment processes

- Continuous process optimization and innovation

Global Service Capability

- Comprehensive service portfolio covering all die casting processes

- International quality standards compliance

- Customized solutions for specific application requirements

Customer-Centric Approach

- Flexible production capabilities to meet diverse needs

- Responsive technical support and engineering assistance

- Competitive pricing with reliable delivery schedules

Get in Touch with Leesh

For inquiries about Leesh’s gravity die casting T6 treatment services or to discuss your specific requirements, please contact:

David Lee

Phone: +86-135-16085845

Experience the difference of precision engineering with Leesh’s gravity die casting T6 treatment – where quality meets performance in every component.