Leesh Holdings Co., Ltd. (Leesh), a leading engineering and manufacturing company based in Shenyang, China’s Heavy Industry Center, offers premium Induction Hardening services to global clients. As a multifaceted enterprise, Leesh specializes in various engineering and manufacturing solutions, with Induction Hardening being one of their core capabilities in the field of heat treatment.

What is Induction Hardening?

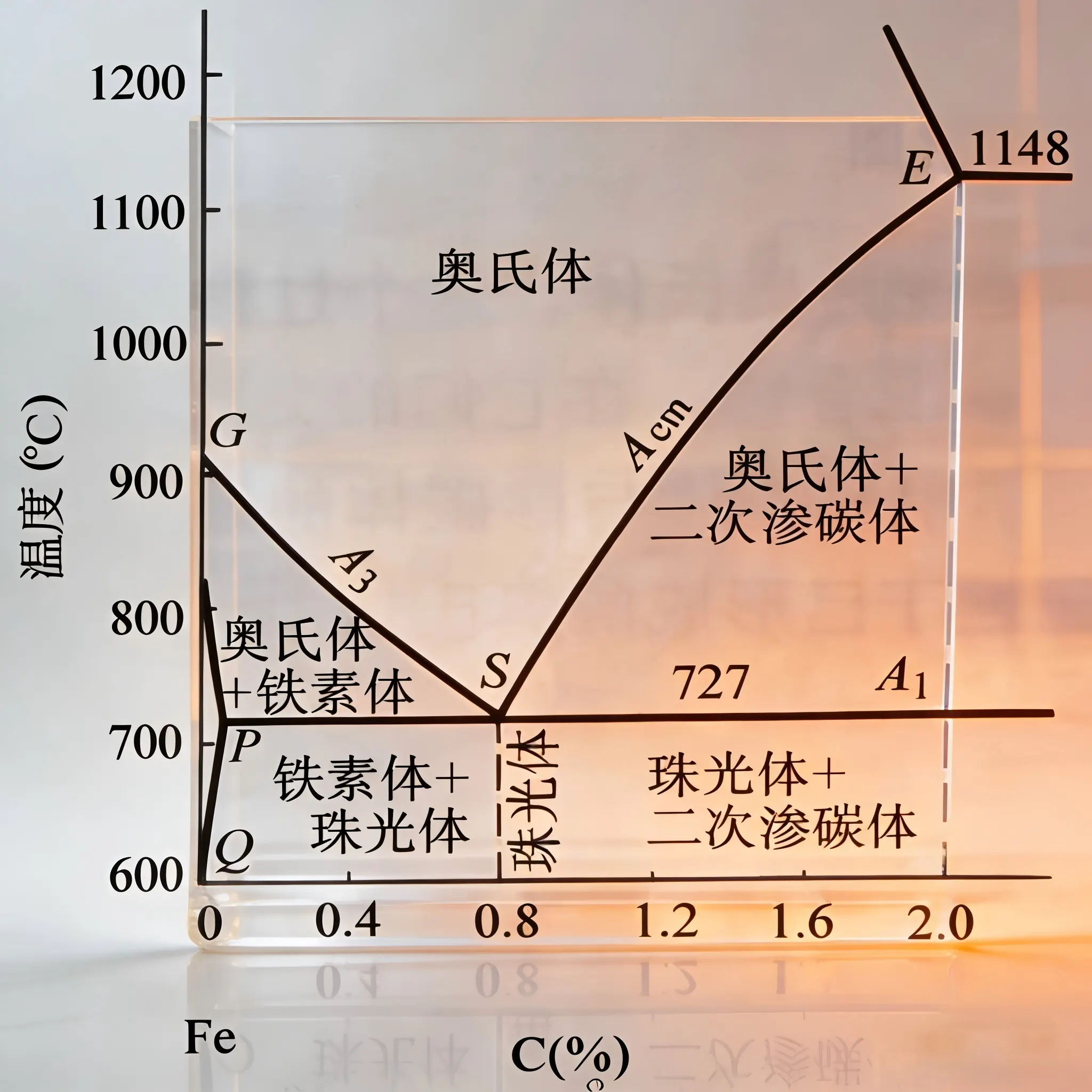

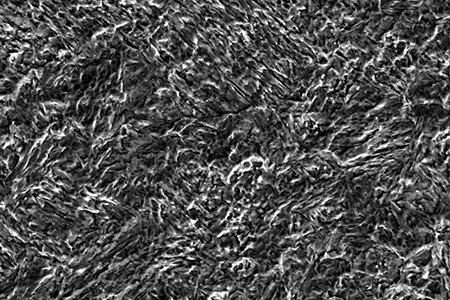

It is a specialized heat treatment process that significantly enhances the surface properties of metal components. This technique involves heating a metal part using electromagnetic induction and then rapidly quenching it. The result is a martensitic transformation in the metal, which increases both the hardness and brittleness of the treated surface layer while maintaining the toughness of the core material.

One of the key advantages of Induction Hardening is its ability to selectively harden specific areas of a part or assembly without affecting the overall properties of the component. This targeted approach allows for optimal performance in critical applications where wear resistance is essential.

Leesh’s Induction Hardening services are widely utilized in various industries for critical components that require high wear resistance. Common applications include:

- Automotive Industry: Drive shafts, gears, springs, and other mechanical parts subject to significant wear.

- Heavy Machinery: Components used in construction equipment, agricultural machinery, and industrial tools.

- Power Transmission: Bearings, axles, and other load-bearing components.

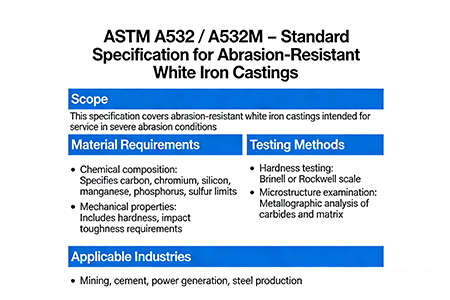

The process is particularly effective for low alloy medium carbon steels, which are commonly used in critical applications demanding superior wear resistance.