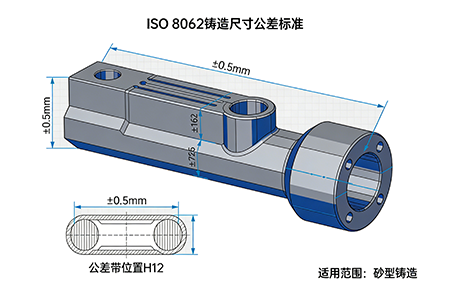

ISO8062 is the most widely spread casting tolerance standard, CT5 to CT7 is the investment casting general casting tolerance.

Leesh Holdings foundry use ISO8062 as our most popular use casting tolerance standard:

CT5-CT7- Investment Casting– Silicon Sol Method

CT7- Investment Casting– Water Glass Method

CT8-CT9- Sand Casting – Machine Molding

Over CT9 – Sand Casting- Manual Molding

High Tolerance Control - Investment Casting Supplier

Call us +86 135 1608 5845 or email us at: info@leesh.cn

ISO Casting Dimensional Tolerance Standard ISO8062 (GB/T6414) CT5-CT7

| Nominal Dimension (mm) | CT4 | CT5 | CT6 | CT7 | CT8 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| > | ≤ | Tolerance | Bilateral Tolerance | Tolerance | Bilateral Tolerance | Tolerance | Bilateral Tolerance | Tolerance | Bilateral Tolerance | Tolerance | Bilateral Tolerance |

| — | 10 | 0.26 | ±0.13 | 0.36 | ±0.18 | 0.52 | ±0.26 | 0.74 | ±0.37 | 1 | ±0.5 |

| 10 | 16 | 0.28 | ±0.14 | 0.38 | ±0.19 | 0.54 | ±0.27 | 0.78 | ±0.39 | 1.1 | ±0.55 |

| 16 | 25 | 0.3 | ±0.15 | 0.42 | ±0.21 | 0.58 | ±0.29 | 0.82 | ±0.44 | 1.2 | ±0.6 |

| 25 | 40 | 0.32 | ±0.16 | 0.46 | ±0.23 | 0.64 | ±0.32 | 0.9 | ±0.45 | 1.3 | ±0.65 |

| 40 | 63 | 0.36 | ±0.18 | 0.5 | ±0.25 | 0.7 | ±0.35 | 1 | ±0.50 | 1.4 | ±0.70 |

| 63 | 100 | 0.4 | ±0.20 | 0.56 | ±0.28 | 0.78 | ±0.39 | 1.1 | ±0.55 | 1.6 | ±0.80 |

| 100 | 160 | 0.44 | ±0.22 | 0.62 | ±0.31 | 0.88 | ±0.44 | 1.2 | ±0.60 | 1.8 | ±0.90 |

| 160 | 250 | 0.5 | ±0.25 | 0.7 | ±0.35 | 1 | ±0.50 | 1.4 | ±0.70 | 2 | ±1.0 |

| 250 | 400 | 0.56 | ±0.28 | 0.78 | ±0.39 | 1.1 | ±0.55 | 1.6 | ±0.80 | 2.2 | ±1.1 |

| 400 | 630 | 0.64 | ±0.32 | 0.9 | ±0.45 | 1.2 | ±0.60 | 1.8 | ±0.90 | 2.6 | ±1.3 |

German Investment Casting Linear Dimensional Tolerance Standard VDG P690

| Nominal Dimension (mm) | Length, Width, Height (mm) | Centre Line Distances (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| From | To | D1 | D2 | D3 | D1 | D2 | |||

| Tolerance | Tolerance Field | Tolerance | Tolerance Field | Tolerance | Tolerance Field | Tolerance | Tolerance Field | ||

| 0 | 6 | ±0.10 | 0.2 | ±0.08 | 0.16 | ±0.06 | 0.12 | ±0.25 | ±0.16 |

| 6 | 10 | ±0.12 | 0.24 | ±0.10 | 0.2 | - | - | - | - |

| 10 | 14 | ±0.15 | 0.3 | ±0.12 | 0.24 | ±0.09 | 0.18 | - | - |

| 14 | 18 | ±0.20 | 0.4 | ±0.14 | 0.28 | - | - | - | - |

| 18 | 24 | ±0.25 | 0.5 | ±0.17 | 0.34 | ±0.12 | 0.23 | ±0.32 | ±0.20 |

| 24 | 30 | ±0.30 | 0.6 | ±0.20 | 0.4 | ±0.14 | 0.27 | - | - |

| 30 | 40 | ±0.37 | 0.74 | ±0.25 | 0.5 | ±0.17 | 0.33 | ±0.50 | ±0.30 |

| 40 | 50 | ±0.44 | 0.88 | ±0.30 | 0.6 | ±0.20 | 0.39 | - | - |

| 50 | 65 | ±0.52 | 1.04 | ±0.38 | 0.76 | ±0.23 | 0.46 | ±0.71 | ±0.45 |

| 65 | 80 | ±0.60 | 1.2 | ±0.46 | 0.92 | ±0.27 | 0.53 | - | - |

| 80 | 100 | ±0.68 | 1.38 | ±0.53 | 1.06 | ±0.30 | 0.6 | ±0.90 | ±0.60 |

| 100 | 120 | ±0.76 | 1.52 | ±0.60 | 1.2 | ±0.33 | 0.66 | - | - |

| 120 | 140 | ±0.84 | 1.68 | ±0.65 | 1.3 | ±0.36 | 0.71 | ±1.15 | ±0.85 |

| 140 | 160 | ±0.92 | 1.84 | ±0.72 | 1.44 | ±0.38 | 0.76 | - | - |

| 160 | 180 | ±1.02 | 2.04 | ±0.80 | 1.6 | ±0.42 | 0.81 | - | - |

| 180 | 200 | ±1.12 | 2.24 | ±0.88 | 1.76 | ±0.43 | 0.86 | ±1.80 | ±1.00 |

| 200 | 225 | ±1.28 | 2.56 | ±0.95 | 1.9 | ±0.47 | 0.93 | - | - |

| 225 | 250 | ±1.44 | 2.88 | ±1.05 | 2.1 | ±0.51 | 1.02 | - | - |

| 250 | 280 | ±1.64 | 3.28 | ±1.15 | 2.3 | ±0.56 | 1.12 | ±2.20 | ±1.25 |

| 280 | 315 | ±1.84 | 3.68 | ±1.25 | 2.5 | ±0.63 | 1.26 | - | - |

| 315 | 355 | ±2.10 | 4.2 | ±1.40 | 2.6 | ±0.71 | 1.42 | ±2.60 | ±1.60 |

| 355 | 400 | ±2.40 | 4.8 | ±1.60 | 3.2 | ±0.80 | 1.6 | - | - |

Notes for VDG P690:

- D1: General dimension tolerances for general use

- D2: Applicable to important dimensions requiring tight tolerances

- D3: Premium tolerance – requires additional operations such as correction to achieve, applicable only to a few special dimensions with specific requirements

Additional Casting Tolerances

Casting Angular Tolerance: ± 0.5° ~ ± 1°

Casting Straightness: Error of 0.127mm per 25mm

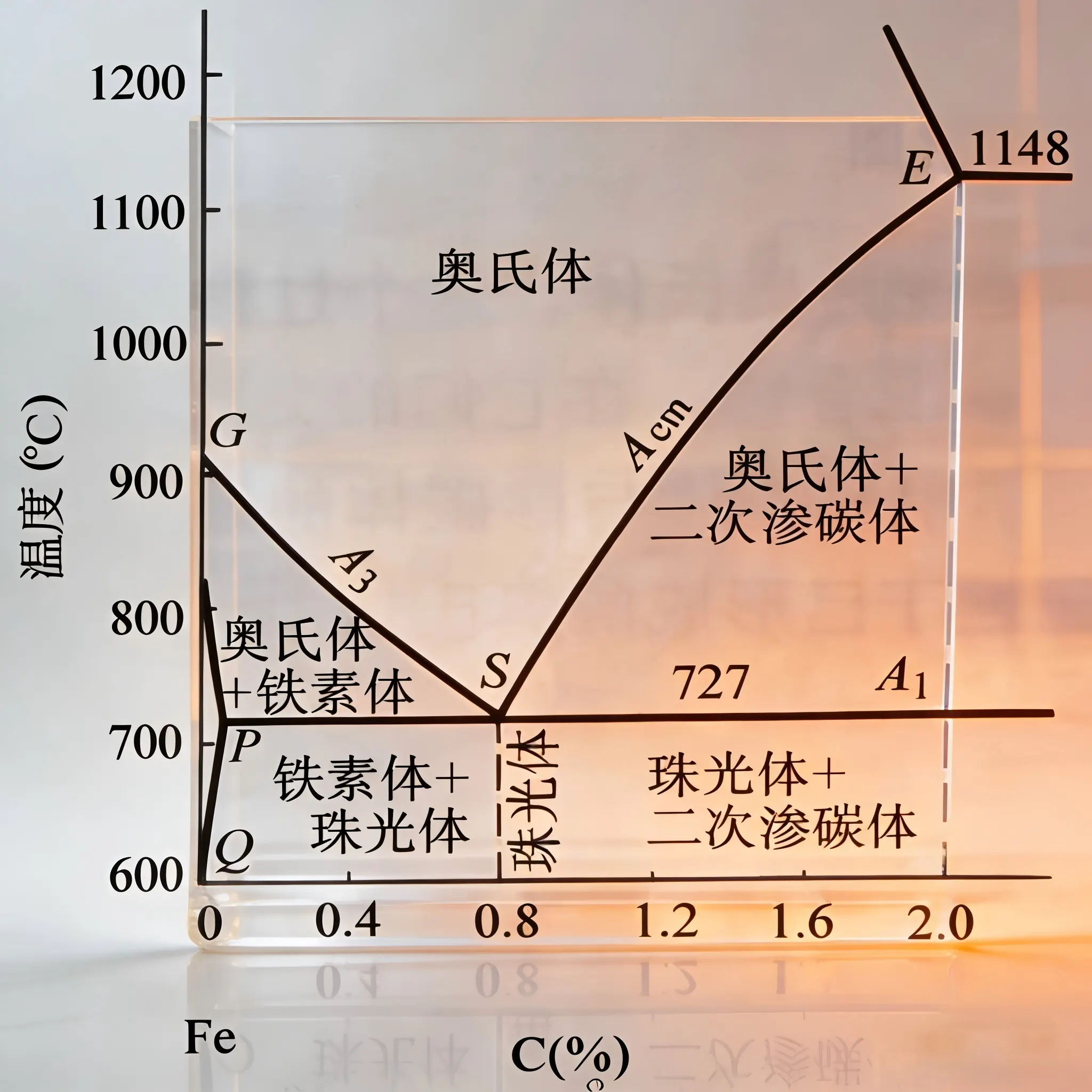

Heat Treatment Training Seminar

Heat Treatment Training Seminar

CopyRight@Leesh...

Comprehensive casting tolerance guide: ISO 8062 (GB/T6414) CT5-CT7 linear tolerances, VDG P690 investment...

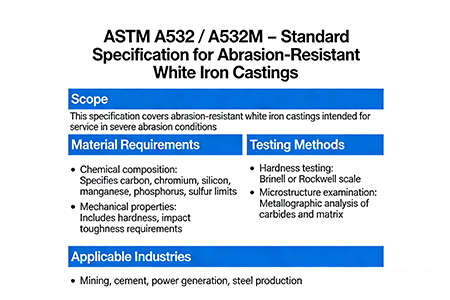

Abrasion Resistant White Iron Castings ASTM A532 / A532M

Method of Manufacture

These alloys may...

Dear all attention:

All molds/moulds/toolings and drawings are the assets and property of our customers....

As 2025 draws to a close, we want to take a moment to thank our outstanding team, trusted customers,...

GOST 613-79: Tin Foundry Bronzes Standard

GOST 613-79: Tin Foundry Bronzes. Grades

Standard Information

Standard...

ZG06Cr13Ni5Mo High Strength Martensitic Stainless Steel Castings

International Equivalent Grades:Chinese...

Leesh is a key player in the Gravity Die Casting with specialized experience, enhanced with T6 heat treatment...

Leesh Holdings Co., Ltd. (Leesh), a leading engineering and manufacturing company based in Shenyang,...

Understanding the Difference Between Surface Roughness and Surface Finish

In the field of mechanical...

No posts found