1st July, Leesh and China Textile Machinery Group have singed first 10 Tons Textile Machinery parts (Investment Casting) contract at the Liaoning Mansion Hotel.

This contract is considered the mutual benefits, and also has strategic move for both of us. At the right time, Leesh is starting engaging in Textile Machinery industry and China Textile Machinery group wants to improve their machinery level and export to south Asian market.

We are looking forward has 10% increase of our business in the next 5 years.

Investment Casting Stainless Steel Alloy Centrifugal Pump Body Castings

Stainless Steel & Copper Alloy Centrifugal, Turbocharger & Multistage Pump Impellers | Investment Casting

Investment Cast Check Valve Bodies & Discs | Precision Custom Valve Castings

Customized Silica Sol Lost Wax Casting Parts | Buy High-Quality Casting Products

Precision Casting & Mold Making | Alloy Casting Heat Treatment Services

Precision Casting Materials | Stainless Steel Precision Casting & High-Temperature Alloy

Precision Casting Services | Custom Wax Pattern, Ceramic Shell, Lost Wax Process

Custom Investment Casting Manufacturer | High-Quality Precision Cast Parts

Custom investment casting slot bushing stainless steel cast center bracket T-type sleeve

Steel Foundry OEM Custom Stainless Steel CF8 Investment Casting parts

All material will supply chemical and mechanical report, heat treatment report , dimension reports and further reports asked by customers.

Silicate Investment Casting Urea core casting Ceramic Core lost wax casting for tube cavities

China foundry investment casting stainless steel grade vavle body

Chemical composition of A351 stainless steel casting

Process: Investment Casting / lost wax casting / water glass casting

Industry: For corrosion industry

motor investment casting Top notch carbon steel gear

professional customized investment casting supplier

Steel, gray iron, ductile iron, stainless steel, aluminum, etc

China Investment Casting Suppliers lost wax casting part

lost wax casting part

precision casting

stainless investment castingChina Investment Casting Suppliers lost wax casting part

OEM Precision Casting Lost Wax Investment Casting Parts Marine Propeller Blade Stainless Steel Impeller Turbine Blade Impeller Turbine Turbine Turbo Impeller

investment casting supplier investment casting lost wax casting customized metal casting parts

lost wax casting

customized metal casting parts

casting service

Product description: investment casting supplier investment casting lost wax casting customized metal casting parts

China foundry investment casting foundry lost wax casting process part

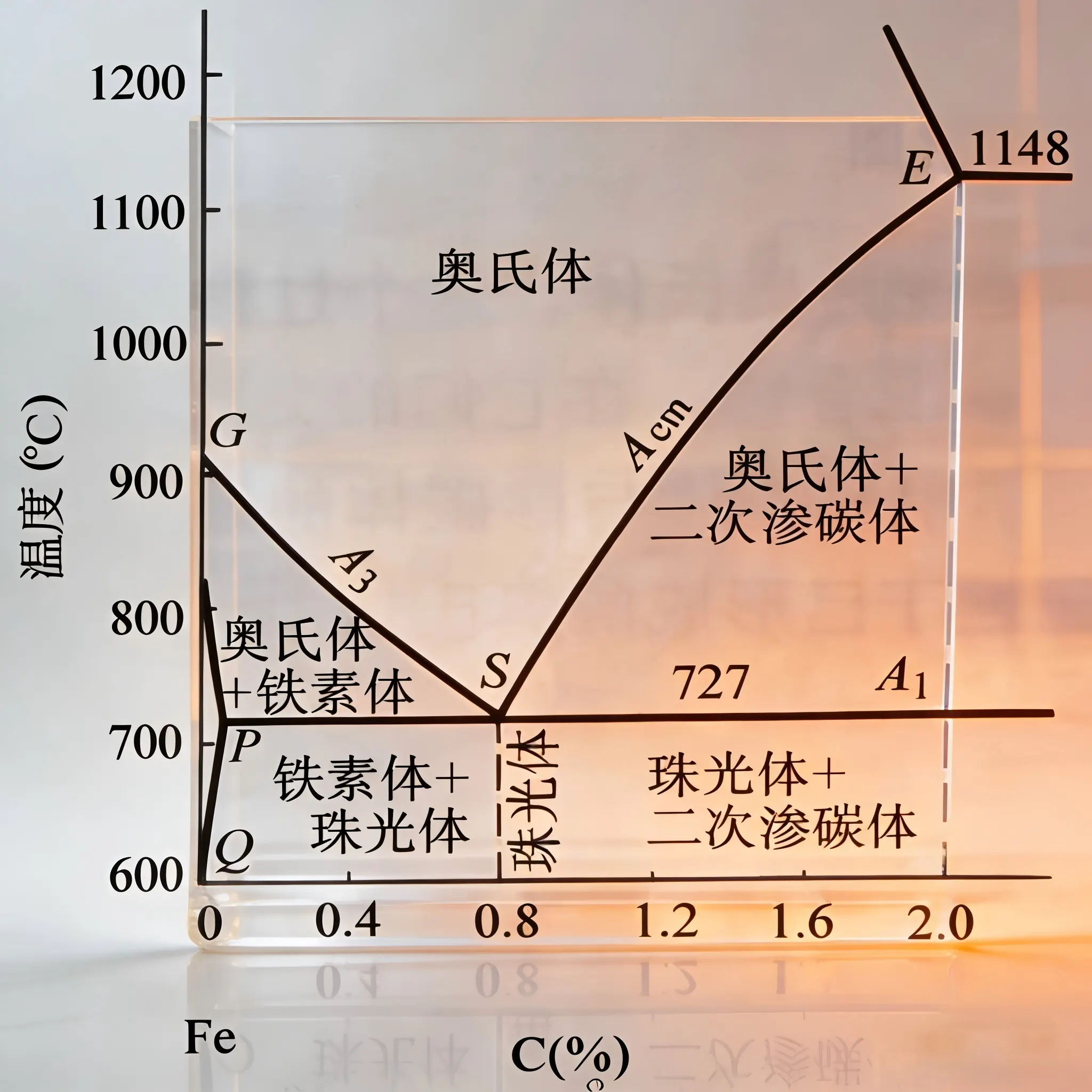

Investment casting, also known as lost wax casting, is a casting method in which a pattern is made of a melt-able material, then coated with several layers of refractory material to form a shell, and the pattern is melted away after high-temperature firing, and then the molten metal is poured into the shell.

Investment casting have high precision and high surface quality, with small machining allowances, which can achieve less or no machining requires. Investment casting can cast complex thin-walled parts with complex shapes (the minimum wall thickness can reach 0.25-0.4mm), and the smallest hole diameter can reach 2.5mm.

Leesh holdings is the key leading supplier of investment cast parts to both China market and global market.Through many years development, our casting parts now services in railway, automobile and truck, construction machinery, mining machinery, forklift truck, agricultural machinery, ship, petroleum machinery, construction, pump valve, mechanical and electrical, hardware tools, electric power equipment, etc.

Leesh capability

Method: Investment Casting, Lost Wax Casting, Precision Casting

| Process Description | Process Control | |||

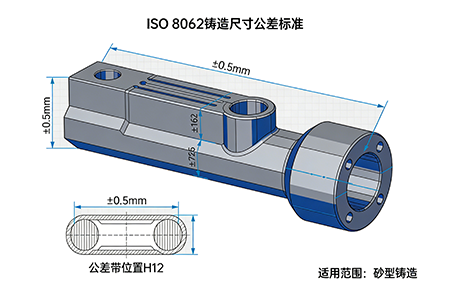

| Mass(kgs) | General Tolerance Standard | Casting Tolerance(CT) | Surface Rougness(μm) | |

| Silicon Sol | 0.005-50 | ISO 8062 | CT4-CT6 | Ra 3.2~6.3 μm |

| Water Glass | 0.10-100 | ISO 8062 | CT6-CT8 | Ra 6.3~12.5 μm |

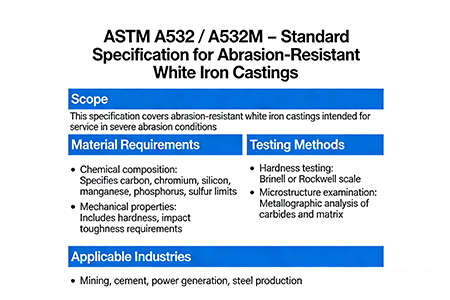

Material: Stainless Steel (General SUS304, SUS316, 1.4301), etc.,Stainless Iron (General 201, 420, 430), etc.,High/Middle/Low Carbon Steel (A3, Q235, 45), etc.,Alloy Steel (General 20cr, 20crmo, 20crnimo, 40cr, 40crmo, 40crnimo, 42cr, 42crmo, 42crnimo) etc.,Brass (H59, H62, H75, H80), etc.,

Red Copper, Bronze, White Copper and other materials.

The above list Is For Reference Only, If You Have Special Needs, Please Contact Customer Service Staff.

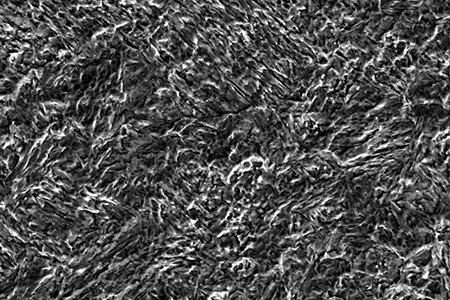

Post Casting Process: Ordinary Polishing, Mirror Polishing, Electrolytic Polishing, Brushed Finishing, Grinding, Heat Treatment, Finishing, Drilling and Tapping,Plating, etc

Surface Treatment: polishing, powder coating, zinc plating, chrome plating,heat treatment,tumbling polishing, electro-polishing.