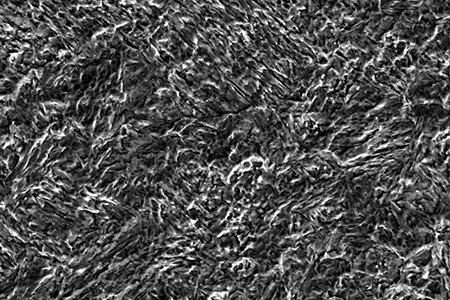

Leesh Silica sol precision casting (also known as investment casting or lost-wax casting) is built on advanced equipment, mature techniques, and extensive experience, ensuring that our products’ surface roughness consistently ranks among the best in the industry, typically achieves a surface roughness influenced by multiple factors, including silica sol coating quality, shell mold preparation, and metal pouring temperature.

The standard roughness range is as follows:

1. General Range

- Ra 1.6–6.3 μm (common industrial standard)

- Rz 10–40 μm (peak-to-valley roughness)

2. Variations Based on Process Level

- Standard Silica Sol Casting: Ra 3.2–6.3 μm (slight texture visible, suitable for general structural parts).

- High-Precision Silica Sol Casting:

- Ra 1.6–3.2 μm (achieved by optimizing shell molds, fine coatings, and strict process control).

- In rare cases, Ra 0.8–1.6 μm can be achieved (usually requiring post-casting polishing or electrolytic treatment).

3. Key Influencing Factors

- Shell Mold Quality: The particle size of silica sol binders and refractory materials (e.g., zircon flour or alumina) directly affects surface finish.

- Wax Pattern Surface: The initial roughness of the wax pattern (typically Ra 0.8–1.6 μm) is critical.

- Dewaxing & Firing: Improper dewaxing or sintering can cause shell cracking or surface defects.

- Metal Pouring: Excessive temperature or turbulence may increase oxidation or roughness.

4. Post-Casting Treatments

For lower roughness (e.g., Ra <0.8 μm), additional processes may be applied:

- Mechanical polishing, sandblasting, or electropolishing.

- Surface coatings (e.g., electroless nickel plating).

5. Comparison with Other Casting Methods

- Sodium Silicate (Water Glass) Investment Casting: Ra 6.3–12.5 μm (relatively rougher).

- Die Casting: Ra 0.8–3.2 μm (but limited to non-ferrous alloys).

Recommendations

If high surface finish is required, roughness targets should be defined early in the process design phase. Optimization of shell layers (e.g., reinforcing backup layers, refining face coats) and sintering parameters through testing is recommended. Prototype inspection is advised to confirm actual values in production.

So if you have any further assist need, please just feel free contact Leesh Sales or engineer, we are waiting for your message!

info@leesh.cn, or call direct +86 135 1608 5845