C86500 Is a kind of copper alloy material, mainly used in chemical machinery and equipment, with high electrical conductivity, thermal conductivity, corrosion resistance and mechanical strength characteristics.

C86500 Copper by adding the right amount of tin, zinc and other elements, significantly improve the corrosion resistance and mechanical strength of the material, so that it can maintain long-term stability and durability in the face of common acid, alkali, salt and other corrosive media in the chemical environment .

In addition, C86500 copper material also has good processing performance, suitable for Leesh sand casting, investment casting, forging, and machining processes,, can meet the needs of complex chemical equipment.

Chemical composition and physical properties

The specific chemical composition of C86500 includes copper (Cu), tin (Sn), zinc (Zn) and other elements. These ingredients make the C86500 copper material not only inherit the high electrical conductivity and good thermal conductivity of the copper, but also significantly improve the corrosion resistance and mechanical strength of the material by adding an appropriate amount of tin, zinc and other elements.

Application

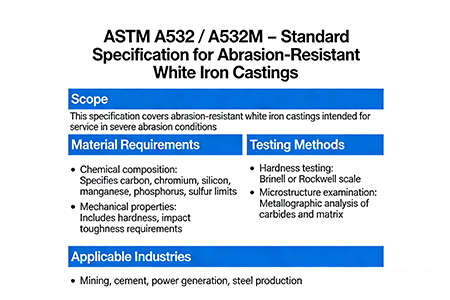

C86500 Copper Alloy is widely used in chemical machinery and equipment, suitable for a variety of complex chemical equipment design requirements, can prolong the service life of equipment and improve the overall performance of equipment. With the continuous development of the chemical industry, the requirements for equipment and materials are increasingly stringent. C86500 copper has gradually become one of the preferred materials in chemical machinery and equipment manufacturing with its excellent corrosion resistance, high strength and good processing performance.

| Similar or Equivalent Specification | |||||||

| CDA | ASTM | SAE | AMS | Federal | Ingot# | Military | Other Desc |

| C86500 | B505 | 430 C | 4860 | QQ-C-390B TYPE III | 421 | MIL-C-22229 COMP 7 | HIGH STRENGTH YELLOW BRASS |

| J461 | QQ-B-726 CLASS A | ||||||

| J462 | |||||||

| 化学成分 (according to ASTM B505-08) | |||||||||||

| Cu% | Sn% | Pb% | Zn% | Fe% | Ni% | Sb% | P% | S% | Al% | Mn% | Si% |

| Note: Single values represent maximums.注意单一数值代表最大值 | |||||||||||

| A In determining copper minimum, copper may be calculated as copper plus nickel. | |||||||||||

| 55.00-60.00 | 1 | 0.4 | 36.00-42.00 | 0.40-2.00 | 1.0A | N/A | N/A | N/A | 0.50-1.50 | 0.10-1.50 | N/A |

| 机械性能(according to ASTM B505-08) | ||||||

Tensile Strength(min) | Yield Strength(at .5% extension under load min) | Elongation(in 2in. or 50mm min, %) | Brinell Hardness(min) | Remarks | ||

| Ksi | MPa | Ksi | MPa | |||

| 70 | 483 | 25 | 172 | 25 | N/A | |

| Machinability加工性能 | ||

| 合金 | Rating | 密度 |

| C86500 | 26 | 8.33 gm/cm3 @ 20 C |

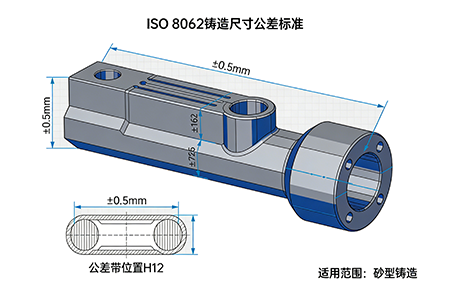

Leesh Process:

sand casting & investment casting can pour C86500 and equivalent grade

Forging

Machining